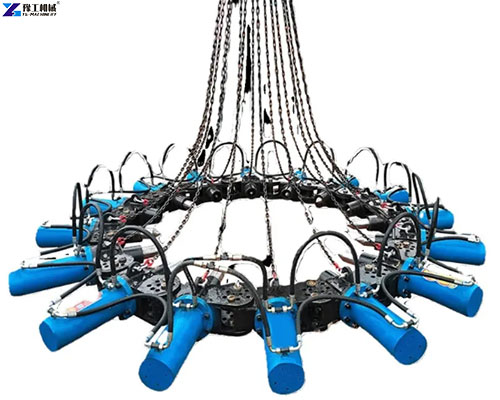

Pile crusher is a construction machine specially designed for removing concrete pile heads, especially suitable for pile foundation projects such as high-speed railway bridges and civil engineering buildings. Its core working principle is to drive multiple cylinders through a hydraulic power source to squeeze the pile body with the drill rod to achieve rapid truncation of the pile head. The concrete pile crusher adopts a modular design, and the number of modules can be freely combined according to the pile diameter to meet different construction needs. YG provides you with different models of pile breakers. Click to get the factory price!

Pile Crusher Parameter

| Module Number | PCS | 4 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| Combination of the total weight | KG | 1600 | 2640 | 2970 | 3300 | 3630 | 3960 | 4290 | 4620 | 4950 | 5280 | 5610 | 5940 |

| Pile diameter range | mm | 400-600 | 600-800 | 800-1000 | 1000-1150 | 1150-1300 | 1300-1500 | 1500-1650 | 1650-1800 | 1800-1970 | 1970-2200 | 2200-2360 | 2360-2500 |

| Hydraulic excavator | T | 20T-30T | 30T-40T | Hydraulic system/pump station | |||||||||

| Max.Thrust | 300KN | Max.Cylinder required | 20L/min | Machinery Tonnage | ≥20T | Location pinΦ35 | |||||||

| Max.Cylinder Trip | 300mm | Chisel diameter | 110mm | Single module weight | 335KG | ||||||||

| Max.Cylinder Pressure | 300MPa | Max.Hoist Capacity | ≤500mm | Singlemodulesize | 1015*865*340mm | ||||||||

4 Features of the Concrete Pile Breaker

- High efficiency and energy saving. Hydraulic drive technology makes the pile breaker powerful. Taking a pile head with a diameter of 1 meter as an example, the pile breaker can be completed in only 10-15 minutes, and 20-100 pile heads can be processed per day.

- Easy to operate. The equipment can be connected and used with construction machinery such as excavators and cranes. No professional skills are required, it is easy to get started, and the labor cost is reduced by 70%.

- Durable and reliable. Made of high-strength alloy steel. It can maintain stable performance even under complex geological conditions.

- Very low noise during operation. Full hydraulic drive technology achieves low noise operation (≤70 decibels), avoiding dust and vibration pollution caused by traditional blasting or pneumatic pick operations.

Why Choose a Hydraulic Pile Crusher?

There are many disadvantages of traditional manual pile breaking or blasting methods:

- Inefficiency: Manual pile breaking relies on pneumatic picks or blasting, which is slow and easily affected by weather.

2 High safety risk: Workers need to operate at close range, which is prone to accidents such as falling and splashing. - High cost: The labor cost accounts for a high proportion, and blasting requires professional qualifications and approval, which is time-consuming and labor-intensive.

The Emergence of Pile Crushers Has Completely Solved These Problems

- Time-saving and labor-saving: The daily processing volume of a single machine can reach dozens of times that of manual labor, shortening the construction period by 30%-50%.

- Safe and worry-free: Workers can remotely control and avoid direct contact with the pile heads, and the accident rate is close to zero.

- Strong economic efficiency: The initial investment in the equipment can be recovered within 6-12 months through the saved labor and time costs.

Feedback from Global Pile Breakers Customers

- Philippine customers: A new tool for speeding up infrastructure construction

A highway project in Manila, Philippines, uses YG Machinery pile crushers, which process more than 50 pile heads per day. The project leader said, “The equipment can still operate stably in rainy and humid environments. The modular design allows us to quickly adapt to different pile diameter requirements, and the efficiency is 4 times higher than traditional methods!” - Romanian customer: a model of durability in severe cold climates

In a residential area project in Bucharest, Romania, the YG pile breaker worked continuously in low temperatures for 3 months without any failure. The engineer commented: “The hydraulic system starts quickly in extremely cold environments, the module joints are well sealed, and the steel bar retention rate is 99%.” - Ecuadorian customer: a pile breaker expert in complex terrain

In a hydropower station project in Quito, Ecuador, the YG pile breaker operated flexibly in the muddy terrain of the mountainous area and successfully handled an ultra-large pile head with a diameter of 1.8 meters. The project manager praised: “The equipment can be perfectly matched with local excavators, has strong climbing ability, and the pile breaking accuracy is controlled within ±2cm, which completely solves the problem that traditional equipment cannot enter!”

Concrete Pile Breaker Factory-YG Machinery

As a leader in the pile crusher industry, YG Machinery has always been committed to combining technological innovation with customer needs. With its high efficiency, safety, and environmental protection, the pile crusher has become the preferred equipment for pile foundation projects around the world. As an industry benchmark, YG has won the trust of customers with advanced technology and high-quality services. Whether it is rainy Southeast Asia, cold Eastern Europe, or complex South American terrain, YG pile breakers can provide you with reliable pile-breaking solutions. Come and contact us for equipment details!