Pavement cracking is a common problem in road maintenance work. It not only affects the beauty of the road but also accelerates road damage due to rainwater infiltration. At this time, an efficient pavement grouting machine is especially important, and YG Machinery, as a professional crack filling machine manufacturer, is highly favored by the market. Today, let’s learn more about YG’s high-quality crack sealing machine. Click on contact us to get the latest quote for a grouting machine!

Crack Sealing Machine Parameter

| Model | YG-50L | YG-80L | YG-100L |

| Hopper volume | 50L | 80L | 100L |

| Discharge method | Self flow | Asphalt pump feed | Asphalt pump feed + hand-held tube |

| Heating method | Liquefied gas | Liquefied gas + heat transfer oil | Italian diesel burner, heat transfer oil cycle heating |

| Temperature control | Temperature sensor 180 ° (temperature control call) | Temperature sensor 180 ° (temperature control call) | Automatic temperature control system |

| Filling speed | 10m/min | 15m/min | 20m/min |

| Length of sealing pipe | —— | —— | 5m |

| Walking mode | Push-type + brake device | Push-type + brake device | Push-type + trailer |

| Mixing method | Manual mixing | Manual mixing | Electric stirring |

| Power Configuration | Solar panels + batteries | Solar panels + batteries | Import 2KW generator |

| Dimensions | 1200*700*1200mm | 1200*700*1200mm | 1750*786*1200mm |

| Weight | 120kg | 150kg | 220kg |

Customers on the Use of the Asphalt Crack Filler Machine

- The road maintenance department in Romania uses YG pavement grouting machines when faced with a large number of road cracks. Its efficient working ability enables the road sections that originally needed a long time to be repaired to be grouted quickly, which greatly improves the efficiency of road maintenance and guarantees the normal use of the road.

- In the Czech Republic, municipal engineering teams use YG pavement grouting machines to maintain city streets. The machine is easy to operate, and workers can quickly and accurately grout cracks, keeping city roads in good condition and improving the city’s image.

- YG road grouting machines also performed well in some highway projects in South Africa. In the face of complex road conditions and harsh environments, it operates stably and injects high-quality grouting materials into the cracks accurately, which effectively extends the service life of the highway and reduces the maintenance cost in the later stage.

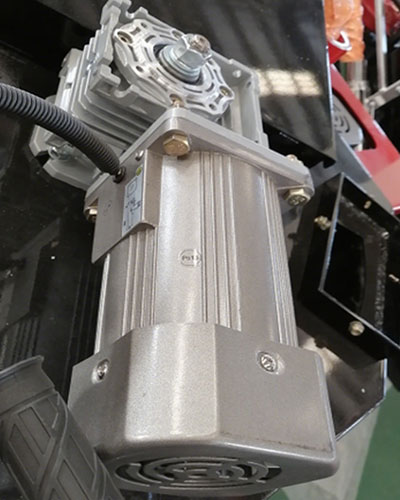

output pump motor mixer machine discharge nozzle with scraper

3 Advantages of the YG Crack Filler Machine

- High efficiency melt, save time. The YG Machinery pavement grouting machine adopts advanced heating technology, which can melt the grouting material quickly. Like the liquefied gas combustion with a heating furnace for indirect heating of thermal oil, plus built-in flue secondary heating, so that the efficiency of melting material is greatly improved.

- Precise grouting, reliable quality. Grouting method using 250W electronic control, infinitely variable speed pump with automatic thermostatic electric heater pressure output. This can accurately control the flow and pressure of the grouting material. Whether it is narrow cracks or wider cracks, they can be handled perfectly.

- Energy saving and environmental protection reduce costs. The equipment is designed to focus on energy saving and environmental protection. The heating system has high thermal efficiency and low fuel consumption, which reduces energy waste and cost. At the same time, the discharge pipe part adopts a constant temperature control system to avoid material scorching and aging.

Road Crack Sealing Machine Workflow

- When the pavement grouting machine is working, the liquefied petroleum gas valve is turned on first, and the liquefied petroleum gas furnace is ignited by the electronic igniter, which heats the heat-conducting oil in the melt box. The heat-conducting oil circulates, causing the asphalt or grouting rubber to melt quickly.

- When the material reaches the proper temperature, start the asphalt pump and extrude the material from the discharge port under pressure.

- During the discharging process, the flexible steering gimbal will track the cracks, so that the discharge spout is always aligned with the cracks, realizing precise grouting.

- If the temperature is low, the generator set will provide power for the whole machine, and the thermostatic control system in the discharge pipe will also be activated to prevent the material from solidifying and ensure the grouting work goes smoothly.

Crack Filling Machine from YG Machinery

As a professional pavement grouting machine manufacturer, YG Machinery has many years of R&D and production experience. From product design to production process, all of them are strictly controlled. The technical team constantly innovates and optimizes product performance according to market demand and user feedback. During the production process, we use high-quality materials and components to ensure that every crack sealing machine has excellent performance and reliable quality. Whether it is a small push-type or a large truck-mounted grouting machine, YG can provide perfect solutions to meet the needs of different customers and different scenarios of road grouting. Choosing a YG road grouting machine is choosing an efficient and professional road crack repair solution. We also produce line marking machines, road rollers, and road shot blasting machines. Click to get your machine factory price!