A cement brick plant is a brick-making equipment that integrates automation and intelligence. It adopts an advanced PLC control system, and works fully automatically from raw material ratio to finished product output, saving a lot of labor. With an advanced hydraulic system, the pressure is stable, making the brick-making process more stable and efficient. The production line is also equipped with an intelligent fault diagnosis system, which will immediately alarm once an abnormality occurs. This is conducive to rapid maintenance and is the core equipment of the modern brick-making industry. Want to get a brick-making machine at a factory price? Click to contact us now!

Cement Brick Plant Parameters

| Block Name | Size (L*W*H)mm | Molding Cycle | QTY/Mould | QTY/hour | Qty/8hr |

| Hollow block | 400*200*200 | 15-20s | 6pcs | 1080-1440pcs | 8640-11520pcs |

| Hollow block | 400*150*200 | 15-20s | 7pcs | 1260-1680pcs | 10080-13440pcs |

| Hollow block | 400*100*200 | 15-20s | 11pcs | 1980-3640pcs | 15840-21120pcs |

| Porous block | 240*115*90 | 15-20s | 15pcs | 2700-3600pcs | 21600-28800pcs |

| Standard brick | 240*115*53 | 15-17s | 30pcs | 6300-7200pcs | 50400-57600pcs |

| Paver | 225*112.5*60 | 20-25s | 15pcs | 2160-2700pcs | 17280-21600pcs |

Brick and Block Machine’s Wide Application

- In municipal construction, high-strength sidewalk bricks and non-slip and wear-resistant slope protection bricks can be quickly produced to ensure the quality of urban infrastructure construction.

- During construction, standard wall bricks that meet national standards can be efficiently produced to speed up construction progress.

- In the creation of garden landscapes, by changing the mold, personalized decorative bricks can be formed with one click, adding unique charm to the garden.

Whether it is a large-scale project or a small project, it can be competent with its flexible production mode and reliable product quality.

YG’s Best-Selling Hydraulic Concrete Block Making Machine Line Models

YG’s QT3-15, QT4-15, and QT5-15 fully automatic cement brick plants are popular for their hydraulic drive technology.

- The QT3-15 can produce 8,000 to 9,000 blocks every 8 hours. This model has a stable output and a small footprint, making it suitable for small and medium-sized production companies.

- The QT4-15 optimizes the hydraulic transmission system, increasing production efficiency by 20%, with an output of 11,000 to 12,000 blocks per 8 hours, which can meet the needs of medium-sized orders.

- The QT5-15 uses a high-power hydraulic pump station and a high-strength body, with strong performance, an output of up to 13,000 blocks per 8 hours, and large orders can be easily delivered. Each model is a good helper for brick making! Tell us your production needs and get the right machine model!

Production of Various Brick Types

- The brick and block machine is powerful. By replacing different molds, it can produce a variety of brick types such as standard bricks, hollow bricks, pavement bricks, and grass bricks.

- With the support of the secondary feeder, it can also produce special brick types such as colored pavement bricks and flower bricks. Colored bricks use layered feeding technology, which is brightly colored and long-lasting.

- Flower bricks can be designed with a variety of patterns to meet the personalized needs of customers and help create a unique architectural appearance.

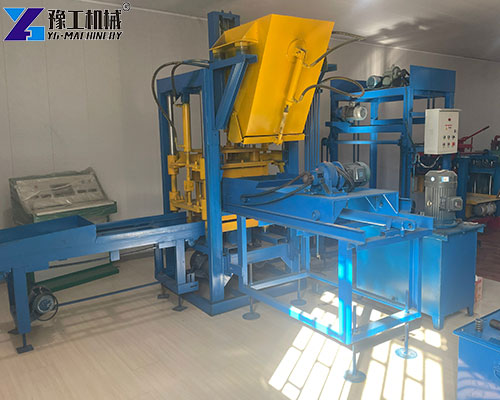

Components of the Block Brick Making Machine Production Line

The cement brick plant consists of many parts.

- The electronic batching bin uses high-precision sensors to accurately mix cement, sand, gravel, additives and other raw materials at the same time, with an error of no more than 1%.

- The mixer uses double-axis forced mixing to ensure that the materials are fully mixed and improve the strength of the bricks.

- The molding host is equipped with multiple sets of mold replacement devices, and the pressing force can reach 200-300 tons to ensure the precise size of the bricks.

- The stacking machine adopts intelligent stacking algorithm to automatically stack the finished products, which are neat and stable and convenient for transportation. All parts work closely together to ensure the efficient operation of the production line.

Working Principle of Brick and Block Machine Production

- The hydraulic concrete block making machine is powered by hydraulic pressure. After the raw materials are accurately proportioned by the electronic batching bin, they are transported to the mixer for full mixing to make concrete materials that meet the requirements.

- The mixed materials are sent to the molding host, and the host presses the materials strongly under the action of hydraulic pressure. After the high-frequency vibration and pressure holding process, the bricks have high density and strength.

- Finally, the stacking machine automatically stacks according to the set program to complete the brick-making process. The operation is simple and easy to use, and novices can quickly master it.

Advantages of YG Brick Making Machine Production Line

YG’s automatic brick machine is very cost-effective!

- Large output, compared with the same type of equipment, energy consumption being reduced by 15%-20%, greatly reducing production costs.

- The main body of the equipment is made of high-strength steel and has undergone a special heat treatment process. It has excellent quality and a low failure rate. Under normal use, the service life can reach more than 10 years and is easy to maintain.

- It also provides a wealth of supporting facilities such as electronic batching bins, stacking machines, and secondary feeders. It can customize solutions according to customers’ production needs and brick type requirements to meet different production needs.

Automatic Brick Machine for Sale- YG Machinery

YG has been deeply involved in the field of cement brick plants for many years and is a recognized professional manufacturer in the industry. Whether you are a large enterprise pursuing high production or a small workshop focusing on special brick types, we can customize it on demand. The electronic batching bin accurately controls materials, the stacking machine efficiently stacks, and the secondary feeder helps produce complex brick types. These supporting facilities are flexibly combined to perfectly adapt to different production needs. We also provide equipment such as concrete mixers, concrete pumps, mobile crushing stations, etc.! Choosing YG means choosing professionalism and reliability! Contact us now and tell us your needs. We will tailor a brick making solution for you to help you easily open a new chapter in your brick making business!