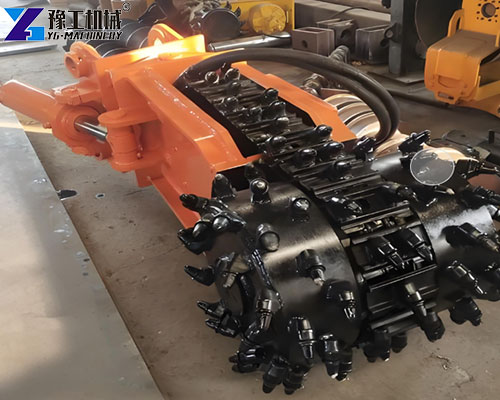

Drum cutter excavator integrates milling, excavation, and leveling functions, providing efficient and controllable solutions for tunnel profiling, mining, demolition, and other complex conditions. Whether facing rock, reinforced concrete, or frozen soil, it can handle the challenge with ease. In addition, YG Machinery also offers double-cylinder hydraulic shears, car dismantling shears, pile breakers, and hydraulic suction cups to meet diverse jobsite needs. Contact us anytime for detailed information and exclusive quotes!【WhatsApp/WeChat/Phone】+86 13837122632

Drum Cutter Excavator Parameters

| Parameter Type | 25 Type | 35 Type |

| Applicable Excavator (T) | 20 – 28 | 30 – 40 |

| Machine Weight (kg) | 1800 | 2500 |

| Milling Width (mm) | 650 | 800 |

| Drum Diameter (mm) | 780 | 780 |

| Machine Length (mm) | 2100 | 2100 |

| Recommended Speed (r/min) | 70 | 70 |

| Recommended Flow (L/min) | 220 | 260 |

| Maximum Pressure (Mpa) | 35 | 35 |

| Maximum Torque (NM) | 18300 | 26000 |

Drum Cutter Excavator Advantages

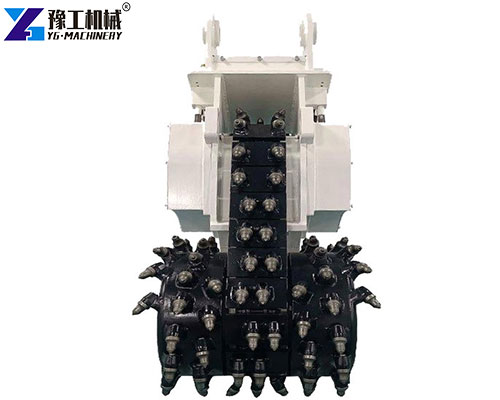

A high-performance drum cutter excavator relies on its internal core technologies, which guarantee outstanding performance even under tough working conditions.

- Strong power and reliable transmission: Equipped with imported high-torque hydraulic motors and high-strength spur gears, it delivers powerful and stable cutting force, ensuring efficient work even in rocks with compressive strength up to 90 MPa.

- Excellent sealing and durable bearings: Key components adopt imported bearings and oil seals, significantly extending the service life of the equipment while also enabling superb underwater operation capability.

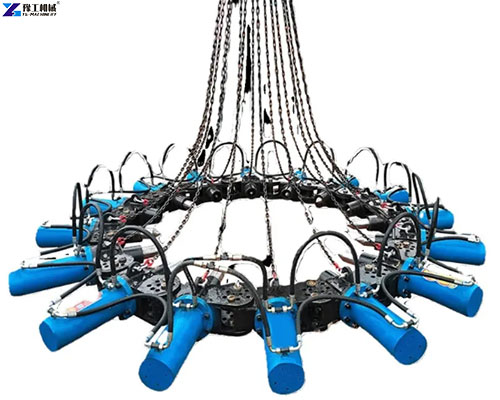

Unique Features of Excavator Drum Cutter Design

Compared with ordinary drum cutters, this excavator drum cutter introduces a major innovation in drum head design, which directly determines work efficiency and cutting results.

- Achieve precise trench milling: Its unique no-blind-zone design eliminates the central gap found in conventional drum heads, allowing for smooth, continuous grooves without side-to-side swinging. The groove width never exceeds the cutter head width, ensuring high precision.

- Improved efficiency and smoothness: This design reduces operator workload, enables faster feed rates, and achieves smoother cutting surfaces—especially ideal for tunnel profiling and road milling where high accuracy is required.

Wide Application Fields

As a multifunctional attachment, the drum cutter attachment is widely used in projects that require precise milling.

- Tunnels and municipal works: Ideal for trenching, tunnel excavation, and profiling, it offers precise non-blasting excavation with minimal disturbance to surrounding structures, ensuring safety.

- Mining and demolition: Used in mines to separate ore and in demolition projects to cut reinforced concrete with precision. Its controllability surpasses traditional breakers, making it suitable for selective demolition.

Key Considerations When Choosing Milling Head for Excavator

Selecting the right milling head for excavator is the first step to successful application, and several factors must be considered.

- Equipment compatibility: The cutter size must match the excavator’s tonnage, hydraulic flow, and pressure. For example, the 25 Type suits 20–28T excavators, while the 35 Type is better for 30–40T carriers to ensure optimal performance and avoid equipment damage.

- Model selection based on jobsite: For wide trenching, the 35 Type with an 800 mm width is more efficient. In tighter spaces requiring flexibility, the 25 Type is more suitable. Additionally, always consider material hardness to ensure torque is sufficient.

Investment Value

Investing in a high-quality milling head for excavator can immediately boost project performance and overall profitability.

- Safety and cost-effectiveness: It provides a non-blasting construction method, greatly improving jobsite safety, while its efficiency reduces machine operating hours and labor, delivering significant ROI.

- Multi-functionality and eco-friendly operation: One machine replaces multiple tools, reducing overall equipment costs. With low vibration, low noise, and minimal dust, it complies with modern environmental standards and is highly suitable for urban construction.

The drum cutter attachment is a revolutionary tool in modern construction, transforming excavators into precise milling platforms. By understanding its parameters, performance benefits, and applications, you can fully unleash the potential of this powerful excavator drum cutter. Whether handling tough rock milling or precision contouring, it is a reliable partner for efficient, safe, and high-quality project completion. Contact us anytime—we are available 24/7!【WhatsApp/WeChat/Phone】+86 13837122632