For any enterprise processing roll materials, investing in a reliable paper slitter rewinder machine is a strategic choice to enhance competitiveness and achieve cost reduction and efficiency improvement. It not only significantly boosts slitting speed and precision, but also brings considerable return on investment for enterprises by reducing waste and ensuring quality.【WhatsApp/WeChat/Phone】+86 13837122632

What Factors Affect the Slitting Precision of a Paper Roll Slitter?

- Tension control system: Stable and adjustable tension is the foundation to keep materials flat, wrinkle-free, and rolls tightly and evenly during slitting.

- Cutter system: The material, hardness, sharpness and installation precision of the blades directly determine whether the cut edges are smooth and burr-free.

- Edge correction system: Automatic edge or linear array correction devices can monitor and correct material deviation in real time, ensuring consistent width of slitting strips.

- Machine rigidity: A sturdy frame and precision bearing blocks can effectively suppress vibration during high-speed operation, guaranteeing long-term stable slitting precision.

Which Is Better, Circular Knife or Flat Knife for a Paper Slitter Rewinder Machine?

- Circular knife slitting: Generally refers to shear slitting with the cooperation of upper and lower circular knives. Suitable for most materials such as paper, film, aluminum foil, etc., it features neat cut edges and high speed, and is one of the most commonly used slitting methods for a paper roll slitter.

- Flat knife slitting: Generally refers to cutting with a single bottom knife matched with a blade. More suitable for slitting adhesive tape, non-woven fabric, thick composite materials, etc., or scenarios with special “flattening” requirements for cut edges, it can avoid material delamination at the cut.

How to Improve Production Efficiency with a Paper Slitter Rewinder Machine?

- Automated processes: Realize automatic feeding, online edge correction, fixed-length cutting and automatic unloading, greatly reducing manual intervention and downtime.

- High-speed and stable operation: Excellent mechanical design combined with servo drive allows the equipment to work continuously and stably at high speed, directly increasing output per unit time.

- Reduce material waste: Precise tension control and cutting precision can maximize the utilization rate of raw materials and reduce waste caused by cutting deviation or uneven rolls.

- Quick order change: Modular design and user-friendly operation interface make changing slitting specifications (cutter position, width) faster, adapting to the flexible production needs of small batches and multiple varieties.

How can Enterprises Choose the Right Paper Slitter Rewinder Machine?

- Clarify core needs: First determine the types of frequently processed materials, thickness range, maximum size of master rolls and target finished product width precision.

- Inspect key configurations: Focus on the control system (whether PLC + touch screen), drive mode (servo motor is better than ordinary motor), brand of the edge correction system and qualification of the cutter supplier.

- Evaluate production efficiency: Compare the maximum mechanical speed, actual working speed, roll change preparation time, etc.

- Value long-term benefits: Choose manufacturers with sturdy structures and comprehensive after-sales service to ensure the reliability of the paper slitting and rewinding machine throughout its life cycle.

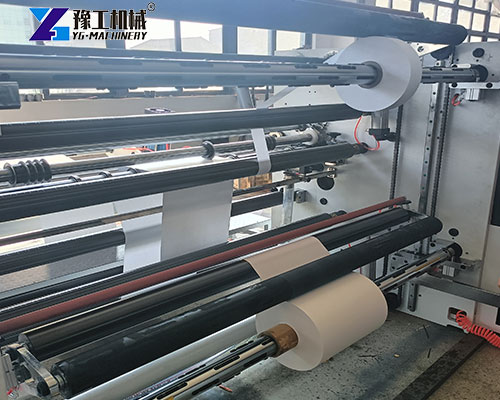

YG Paper Slitting and Rewinding Machine

- Intelligent control: The whole machine adopts PLC control, with functions such as automatic stop at fixed length and material shortage alarm, featuring simple operation.

- Stable operation: The combination of automatic unwinding edge correction and servo-driven rewinding ensures that the rolls remain flat throughout the high-speed slitting process.

- High-efficiency slitting: Optional circular knife/flat knife configuration, with fast slitting speed and high precision; waste edges are automatically removed by a fan.

- Labor saving: From automatic feeding to hydraulic unloading, it greatly reduces the labor intensity of operators, and can be easily operated by one person.

- Durable performance: Key components are made of high-quality materials and advanced craftsmanship with a sturdy structure, ensuring the long-term stable operation of the equipment.

| Model | YG- 1300 | YG- 1600 | YG- 1800 |

| Max width | 1300mm | 1600mm | 1800mm |

| Max Diameter for unwinding | ¢1400mm | ¢1400mm | ¢1400mm |

| Min width of slitting | 30mm | 30mm | 30mm |

| Max Diameter of rewinding | ¢1000mm | ¢1000mm | ¢1000mm |

| Speed | ≤350m/min | ≤350m/min | ≤350m/min |

| Total Power | 24kw | 26kw | 30kw |

| Power supply | 380V/50hz | 380V/50hz | 380V/50hz |

| Weight | 4000kg | 4500kg | 5500kg |

| Overall dimension(LxWxH) | 3300x3150x1930(mm) | 3300x3450x1930(mm) | 3300x3650x1930(mm) |

Contact Us

If you are looking for a professional paper slitter rewinder machine that can improve product quality and production efficiency, YG’s professional team is ready to serve you at any time. According to your specific production needs, we can provide personalized configuration suggestions for a paper roll slitting rewinding machine and comprehensive after-sales service support. Inquiries are welcome, and let us work together to optimize your slitting process.【WhatsApp/WeChat/Phone】+86 13837122632