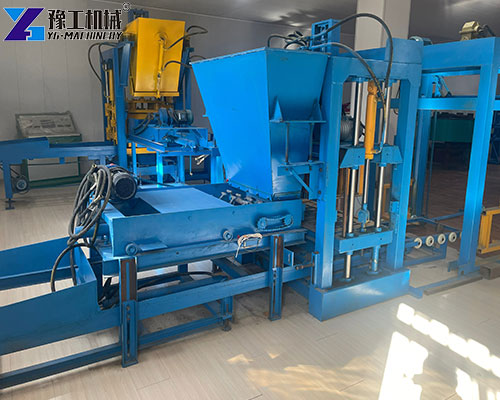

The automatic brick making machine is precision equipment designed to streamline the brick-making process. It does away with labor-intensive traditional methods, dramatically increasing productivity and guaranteeing consistent brick quality. These machines incorporate mechanical, hydraulic, and electrical components to process raw materials into bricks of different shapes, sizes, and strengths. With the ability to produce large quantities in a short period, they have become a must-have for brick manufacturing plants.

Block Brick Making Machine Parameters

| Block Name | Size (L*W*H)mm | Molding Cycle | QTY/Mould | QTY/hour | Qty/8hr |

| Hollow block | 400*200*200 | 15-20s | 6pcs | 1080-1440pcs | 8640-11520pcs |

| Hollow block | 400*150*200 | 15-20s | 7pcs | 1260-1680pcs | 10080-13440pcs |

| Hollow block | 400*100*200 | 15-20s | 11pcs | 1980-3640pcs | 15840-21120pcs |

| Porous block | 240*115*90 | 15-20s | 15pcs | 2700-3600pcs | 21600-28800pcs |

| Standard brick | 240*115*53 | 15-17s | 30pcs | 6300-7200pcs | 50400-57600pcs |

| Paver | 225*112.5*60 | 20-25s | 15pcs | 2160-2700pcs | 17280-21600pcs |

Applications of Automatic Brick Machine

Automatic brick making machine has a wide range of applications.

- In the construction industry, be it residential, commercial, or industrial projects, bricks produced by it are indispensable.

- Building houses, office buildings, factories, or building roads and bridges can provide a stable supply of high-quality bricks.

- In addition, in the field of landscaping and architectural decoration, it can produce beautiful and unique decorative bricks.

What Bricks That the Automatic Brick Making Machine Make?

YG brick making machine is powerful enough to meet a wide range of brick making needs.

- It can produce hollow blocks, which are hollow inside, lightweight and have good heat insulation properties, and are suitable for non-load-bearing walls of buildings.

- Porous blocks are also produced, which are commonly used in the construction of load-bearing walls because of their high porosity and energy-saving effect.

- Standardized bricks, with standard dimensions and high strength, are widely used in all kinds of infrastructure construction.

- At the same time, it can also produce pressure-resistant and non-slip, beautiful, and durable pavement bricks to meet the requirements of sidewalks, plazas, and other places of paving.

Advantages of YG Brick Manufacturing Plant

YG is a famous manufacturer in the field of automatic brick making machines, and the advantages of its products are remarkable.

- Firstly, high production efficiency, YG brick making machine runs fast and can produce a large number of bricks per hour, which can meet the tight schedule.

- Secondly, the quality of bricks is excellent. With advanced technology and precise control, each brick meets high standards of strength, durability, and dimensional accuracy.

- Moreover, these machines are energy-efficient and can reduce operating costs in the long run. It also supports brick customization to meet diversified needs.

Automatic Brick Making Machine Process

The brick making process of automatic brick making machine is interlocked.

- First, carefully select and prepare raw materials such as clay, sand, and cement.

- Then, the raw materials are fed into the mixing chamber of the machine and mixed thoroughly.

- Subsequently, the mixed materials enter the molding area and are pressed under high pressure to form the desired brick shape.

- After molding, the wet bricks are taken out from the machine and placed on the conveyor belt to enhance their strength by natural air drying or maintenance in a specific environment.

- Finally, the finished bricks are checked for quality, packed, and ready to leave the factory.

Automatic Brick Making Machine Price

The price of an automatic brick making machine is affected by many factors.

- The size and capacity of the machine are the key; large capacity, large specification equipment prices are higher.

- The degree of automation and additional features also influence the price. Equipped with an advanced PLC control system, the automatic palletizing and packaging function of the machine is more expensive.

- Brand is also very important, YG Machinery good reputation, reliable performance of the brand, and the price is often on the high side.

- In addition, it is important to consider the cost of raw materials, maintenance costs, and energy consumption over the life of the equipment, all of which are related to the overall price/performance ratio.

YG Machinery’s automatic brick-making machines offer reliable and efficient solutions for brick manufacturing with many advantages. By combining your needs and considering the price-influencing factors, you will be able to choose the right equipment.

Block Brick Making Machine for Sale from YG Machinery

YG automatic brick making machines incorporate advanced mechanical, hydraulic, and electrical technologies with precise control systems to ensure that every brick produced meets high standards of strength, durability, and dimensional accuracy. In terms of production efficiency, the YG brick making machine operates at a high speed and can produce a large number of bricks per hour, which can easily meet the tight schedule of various projects. In addition, the machine has an excellent energy-saving design, which can effectively reduce operating costs in the long run. At the same time, the YG Machinery brick making machine supports diversified brick customization functions, whether it is the standard bricks required for construction or decorative bricks for landscaping, all of which can be produced according to the needs.