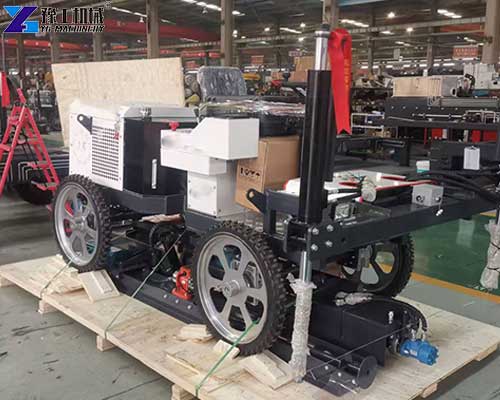

The concrete laser leveling machine is an intelligent construction equipment that integrates laser technology, hydraulic technology, and computer control technology. Compared to the traditional concrete scraper machine, it emits a rotating laser through the laser transmitter, and the laser receiver receives the signal in real-time to automatically control the leveling head, achieving high-precision leveling. The construction personnel only need to operate the equipment to maintain the surface flatness error of the concrete within a very small range, greatly improving the construction quality. Want to improve the smoothness of your concrete? Get a concrete laser screed machine price now!

Concrete Laser Leveling Machine Technical Parameter

| Model | YGJX31 | YGJX32 | YGJX33 | YGJX34 |

| Engine | ||||

| Model | Generator set | GX390 Electric start | GX390 Electric start | GX390 Electric start |

| Power | 2.0kW | 13hp/3600rpm | 13hp/3600rpm | 13hp/3600rpm |

| Fuel tank (L) | 14.5 | 6.5 | 6.5 | 6.5 |

| Running device | ||||

| Drive | Motor | Hydraulic motor | Hydraulic motor | Hydraulic motor |

| Running mode | Infinitely variable speed | Handle control, step-less speed | Handle control, step-less speed | Handle control, step-less speed |

| Running speed(m/min) | 0-36 | 0-45 | 0-65 | 0-45 |

| Suggest working speed(m/min) | 5 | 5 | 5 | 5 |

| Screed head | ||||

| Type | Self-leveling | Electric control, self-leveling | Self-leveling | Hydraulic control, self-leveling |

| Width | 2500mm | 2500mm | 2500mm | 2500mm |

| Exciting force | 500N | 500N | 500N | 500N |

| Vibration frequency | 50Hz | 50Hz | 50Hz | 50Hz |

| Laser control system | ||||

| Control type | Microcomputer laser scan | Microcomputer laser scan | Microcomputer laser scan | Microcomputer control |

| Operation mode | Walk-behind | Walk-behind | Walk-behind | Walk-behind |

| Forward and reverse | Handgrip control, stepless speed-walking | Hydraulic control | Handgrip control, stepless speed-walking | Hydraulic control |

| Size and weight | ||||

| Working size(mm) | 2758*2622*1980 | 2740×2659×1980 | 2578×2643×1980 | 2780*2622*1980 |

| Weight(kg) | 295 | 365 | 380 | 410 |

Laser Concrete Leveling Machine Application

- Concrete laser leveling machine plays a key role in construction in many fields. In the field of industrial manufacturing, new energy vehicle factories and large storage and logistics centers have high requirements for floor accuracy and strength. It can accurately level and compact the ground to ensure the stable operation of production equipment, reduce ground damage caused by frequent rolling of forklifts, and extend the life of the floor.

- In commercial buildings, high-end shopping malls, office buildings, and other places, the flat and smooth ground created by the laser concrete leveling machine not only improves the aesthetics but also reduces the conduction of footsteps and optimizes the comfort of the space.

- In the construction of public facilities, airport runways, port terminals, school playgrounds, and other places have strict ground standards. It can quickly complete high-precision leveling through large-scale continuous construction according to design parameters to meet the needs of special sites. Whether it is industrial, commercial, or public projects, it has become a reliable choice for construction teams with high precision and high efficiency.

Functions and Working Principles of the Concrete Screed Machine

The functions of the concrete screed machine are very powerful. It can not only automatically level and vibrate, and compact concrete, but also carry out large-scale continuous construction, and its efficiency is far higher than that of manual labor. When working, the laser transmitter creates a horizontal reference plane, and the laser receiver captures the signal and feeds it back to the control system, driving the leveling head to move up and down to adjust the height, and cooperates with the spiral spreader to evenly spread concrete, easily creating a high-precision floor.

Customer Feedback on the Laser Screed Machine

Customers who have used the laser screed machine are full of praise.

- Marco, a construction contractor in Italy, said: “After using this equipment, the construction efficiency of our logistics center project in Milan has increased by nearly 3 times. The work that originally required a lot of manual repeated leveling can now be completed quickly and accurately by the machine, and the labor cost has been greatly reduced.”

- Lars, the head of the commercial project in Denmark, gave feedback: “The machine has increased the floor flatness compliance rate of our commercial complex from 80% to 98%. The owner passed the acceptance once and praised our professional construction, which laid a solid foundation for our subsequent cooperation.”

- István, the technical director of an industrial construction company in Hungary, shared: “In the construction of the factory floor, the stability and accuracy of the equipment made us worry-free, and the construction period was shortened, which made the owner very satisfied, and we also won a good reputation.” This real feedback from customers from different countries fully witnessed the excellent performance of the concrete laser leveling machine.

Repair and Maintenance of Floor Screeding Machine

Regular maintenance is essential for the long-term and efficient operation of the laser concrete leveling machine.

- After the daily construction is completed, special tools should be used to clean the residual concrete on the equipment in time to prevent it from drying and affecting the operation of the equipment.

- Check the sensitivity of the laser receiver every week to ensure that its signal reception is accurate, and check whether there is oil leakage in the hydraulic system and deal with it in time.

- The laser system needs to be calibrated every month to ensure the leveling accuracy, and the worn parts, such as scrapers and bearings, should be replaced. Following these simple maintenance operations, you can extend the life of the equipment, reduce maintenance costs, ensure construction continuity, and keep the equipment in the best working condition at all times.

Laser Receiver for Sale from YG

Choosing the right manufacturer means choosing to save worry and money. YG is the industry-leading manufacturer of concrete laser leveling machines. Our equipment has stable performance, convenient operation, strong price competitiveness, and directly provides factory prices. From pre-sales solution customization to worry-free after-sales service, YG escorts you throughout the whole process. We also provide road shot blasting machines, road marking machines, line removal machines, road rollers, and other road-related facilities! Don’t hesitate, choose YG, which means choosing a cost-effective and low-cost construction solution!