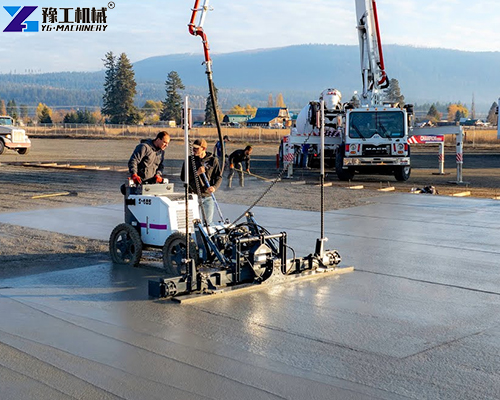

A concrete laser screed for sale is a highly efficient concrete construction machine. Using a laser beam, it precisely controls the height of the screed mechanism, achieving millimeter-level concrete surface flatness. Compared to traditional manual construction methods using scrapers and vibrators, it reduces labor costs by more than half and increases construction speed by over three times. It can easily handle anything from a base layer as thin as 5 cm to a base layer as thick as 30 cm. Contact us now to help you easily handle any type of concrete construction!

Concrete Laser Screed for Sale Parameter

| Model | YG-25-2 | YG-25-4 |

| Motor Power | 3.0kw 220v | 32.5kw 24.2hp |

| Oil Tank Volume | 18L (Work 10h) | 35L |

| Walking Speed | 0-20m/min | 0-55m/min |

| Vibration Motor Speed | 4000rpm | 4000rpm |

| Exciting Force | 2000N | 2000N |

| Vibrating Plate Width | 2500mm | 2500mm |

| Leveling Thickness | 50-250mm | 350mm |

| Laser Control System | American Imported Danfoss | |

| Laser Launcher System | American Tianbao launcher | |

| Laser Receiver System | Switzerland Leica receives | |

| Dimension | 3220*2780*1172mm | 3370*2890*1850mm |

| Weight | 280kg | 800kg |

Specific Applications of Laser Screed Machine

- Floor construction in large industrial plants, often covering tens of thousands of square meters, allows for continuous operation, eliminating the joint problems associated with manual construction.

- Logistics warehouses require high floor flatness. Laser screed machines ensure consistent ground slopes, enabling smoother forklift handling and reducing cargo damage.

- Using laser screed machines for concrete paving in plazas and sidewalks in municipal projects can shorten construction timelines and minimize traffic disruptions.

- It can even be used in highway service areas and bridge deck pavements, making concrete structures more stable.

Features of the YG Concrete Lazer Screed Machine

- The YG Concrete Laser Screed Machine has many outstanding advantages. The operation panel is designed to be as simple as the buttons on a video game console, allowing a novice to operate independently after just one hour of practice following the manual.

- The machine’s width is adjustable, narrowing to a minimum of 1.2 meters, making it suitable for narrow workshop corners. 3. Its laser receiver is extremely sensitive, allowing it to adjust the screed mechanism even with slight surface unevenness instantly.

- Its high-horsepower engine allows it to operate continuously for eight hours without getting hot. Compared to ordinary concrete screed machines, its wear-resistant steel plate is 2 mm thicker, extending its service life by over three years. Furthermore, key components are equipped with protective devices to reduce the risk of malfunctions.

Ride-On Laser Screed Machine: Environmental Performance Characteristics

- YG prioritizes environmental protection. This machine’s engine utilizes electronic fuel injection technology, resulting in a 20% increase in combustion efficiency compared to traditional models and a 1.5 liters/hour reduction in fuel consumption, saving thousands of yuan in fuel costs annually.

- The machine body is equipped with soundproofing pads, resulting in an operating noise level of only 75 decibels, equivalent to the sound of ordinary conversation, which will not disturb nearby residents.

- Exhaust emissions meet China IV standards, and the exhaust from the chimney undergoes multiple layers of filtration, eliminating any pungent odor.

- The machine also recycles wastewater from construction to clean the machine body, conserving water resources and preventing wastewater from flowing across the machine body. This truly combines efficiency and environmental friendliness.

Laser Screed Machine Daily Maintenance

- After each job, flush the machine body with a high-pressure water jet to remove any remaining concrete, paying particular attention to the gaps between the screed blades.

- Check the engine oil weekly. If the oil level drops below the mark, add oil immediately. Wipe the dipstick clean of any oil stains. 3. Check hydraulic hoses regularly and replace them immediately if any cracks are found to prevent oil leaks.

- Check tire pressure monthly and remove any small stones in the tread.

- Lubricate bearings annually to ensure smoother operation. Taking care of these small details will keep your machine in top condition and reduce maintenance costs.

Concrete Lazer Screed Machine for Sale-YG Machinery

YG has been specializing in the production of concrete laser screeds for 15 years. Our production workshop utilizes an automated production line, and each component undergoes three quality inspections before assembly. After purchasing, customers receive a detailed operation video and have access to a 24/7 online technical consultant for any questions. YG’s concrete laser screeds offer high performance, are environmentally friendly, and are durable. We also offer high-quality concrete laser screeds for sale. In addition to this, we also produce concrete mixers, concrete pumps, wall plastering machines, mortar spraying machines, and other related products. Regardless of the size of your project, you can find the right equipment here. Contact us today to significantly improve your construction efficiency!