Want to know how to get efficient road construction solutions at a reasonable concrete laser screed machine price? At present, the market for road laser leveling machines has soared, becoming an indispensable “star equipment” for road and ground construction. Whether it is a large-scale infrastructure project or the ground paving of commercial buildings, it can be seen. Hurry up and learn about it and start a new experience of efficient construction!

Laser screed parameters

| Model | YGJX31 | YGJX32 | YGJX33 | YGJX34 |

| Engine | ||||

| Model | Generator set | GX390 Electric start | GX390 Electric start | GX390 Electric start |

| Power | 2.0kW | 13hp/3600rpm | 13hp/3600rpm | 13hp/3600rpm |

| Fuel tank (L) | 14.5 | 6.5 | 6.5 | 6.5 |

| Running device | ||||

| Drive | Motor | Hydraulic motor | Hydraulic motor | Hydraulic motor |

| Running mode | Infinitely variable speed | Handle control, step-less speed | Handle control, step-less speed | Handle control, step-less speed |

| Running speed(m/min) | 0-36 | 0-45 | 0-65 | 0-45 |

| Suggest working speed(m/min) | 5 | 5 | 5 | 5 |

| Screed head | ||||

| Type | Self-leveling | Electric control, self-leveling | Self-leveling | Hydraulic control, self-leveling |

| Width | 2500mm | 2500mm | 2500mm | 2500mm |

| Exciting force | 500N | 500N | 500N | 500N |

| Vibration frequency | 50Hz | 50Hz | 50Hz | 50Hz |

| Laser control system | ||||

| Control type | Microcomputer laser scan | Microcomputer laser scan | Microcomputer laser scan | Microcomputer control |

| Operation mode | Walk-behind | Walk-behind | Walk-behind | Walk-behind |

| Forward and reverse | Handgrip control, stepless speed-walking | Hydraulic control | Handgrip control, stepless speed-walking | Hydraulic control |

| Size and weight | ||||

| Working size(mm) | 2758*2622*1980 | 2740×2659×1980 | 2578×2643×1980 | 2780*2622*1980 |

| Weight(kg) | 295 | 365 | 380 | 410 |

Application display of concrete laser leveling machine customers

From Europe to the Middle East, and then to America, laser screed equipment has shown its prowess all over the world.

- Hungarian customers use concrete laser leveling machines for ground construction in industrial parks. With its high-precision leveling ability, it can quickly create a ground with excellent flatness and greatly shorten the construction period.

- American customers use floor screeding machines in municipal road construction to efficiently complete large-area road paving, reduce manual errors, and improve project quality.

- In Dubai’s landmark building projects, concrete laser screed machines play a key role, accurately shaping the ground that meets high standards and helping to create a new business card for the city.

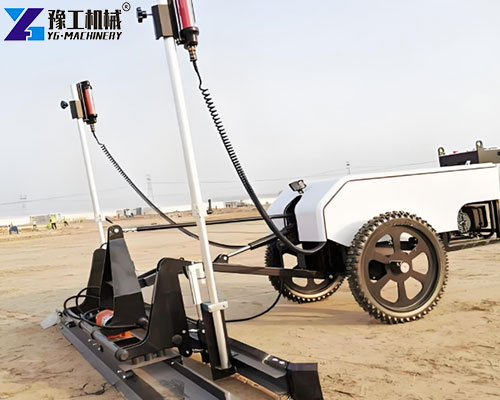

Structural advantages of a floor screeding machine

- It uses the laser control system as the “brain” to monitor and adjust the leveling height in real time.

- With a powerful power system and flexible walking mechanism, it can operate smoothly even in complex terrain.

- The leveling beam is like a “skillful hand” to spread the concrete evenly and accurately level it.

- The laser leveling machine focuses on road leveling and is the basis of road construction. Prepare for the work of road construction equipment such as road marking machines, road joint filling machines, and road shot blasting machines!

How to choose a suitable concrete laser screed machine?

There are many ways to choose reasonable equipment for the concrete laser screed machine price.

- First of all, it is necessary to consider the project. For small home decoration floor renovation, a small and lightweight floor screeding machine is enough, with low cost and flexible operation. For large airport runways or logistics warehouse ground construction, you have to choose a high-power, large-leveling-width concrete laser leveling machine. Although the initial investment is high, the construction efficiency can be increased by 3-5 times, which is more cost-effective in the long run.

- Secondly, the accuracy requirement is a hard indicator. Hospitals and electronic factories, which have extremely high requirements for ground flatness, must choose laser screed equipment with an accuracy of ±2mm. For ordinary parking lots and square construction, equipment with an accuracy of ±5mm can meet the requirements.

- We must also pay attention to the “soft power” of the equipment. For example, the intelligence of the equipment, models with automatic fault diagnosis systems, can reduce downtime and maintenance time.

- The ease of maintenance of the equipment is also critical. Models with modular design make it easier to replace parts, and the later maintenance costs can be reduced by about 40%.

Why does YG laser screed stand out?

Among many brands, YG’s road laser leveling machine stands out with its hardcore strength.

- Let’s talk about durability first. YG uses aviation-grade alloy steel to build the fuselage frame, which is 60% more wear-resistant than ordinary models.

- The ease of operation is even more unique. The original touch-screen human-computer interaction interface allows novices to work independently after 2 hours of training. Compared with traditional models, the operation training time is shortened by half, and the labor cost is naturally greatly reduced.

- Customized service is the exclusive advantage of YG. Whether you are pursuing a high-end project with extreme precision or a small and medium-sized project with a limited budget, the professional team of YG will tailor the equipment configuration plan based on factors such as the construction site, construction period requirements, and budget.

From the basic model to the top model, a reasonable, concrete laser screed machine price can be given to ensure that each device can reach its maximum value.

Concrete laser screed machine price in YG Machinery

In the field of road and ground construction, the road surface laser leveling machine has long become the core equipment for improving the quality and efficiency of the project. Its importance is self-evident. The precise leveling ability directly determines whether the construction results meet the standards. The road surface laser leveling machine provided by YG is the only choice to meet customer needs. Regardless of the size of the project and the precision requirements, YG can match the most suitable equipment for customers with its rich product line and professional customization capabilities. It does not blindly pursue high prices and high configurations, nor does it sacrifice quality to reduce costs, just to allow every customer to get a construction tool far beyond expectations at a reasonable concrete laser screed machine price.