The concrete portable batch plant is a device that mixes cement, sand, gravel, water, and other raw materials in proportion. Traditional mixing plants are fixed and difficult to move. The concrete portable batch plant has more advantages – it can be flexibly moved and quickly installed, making it suitable for projects with variable sites. YG’s mobile concrete plant adopts a modular design. It can be transported by ordinary trucks after disassembly. It only takes 3-5 days to install, greatly saving time and cost. The equipment has low energy consumption and saves 20% more electricity than similar products.

Concrete Portable Batch Plant Parameter

| Model | YG20 | YG30 | YG60 | YG100 |

| Production capacity (m3/h) | 20 | 30 | 60 | 100 |

| Concrete mixer | YG500 | YG750 | YG1500 | YG2000 |

| Aggregate feeding mode | Belt conveyor | Belt conveyor | Belt conveyor | Belt conveyor |

| Aggregate size(mm) | 80/60 | 80/60 | 80/60 | 80/60 |

| Discharging height(m) | 1.5 | 1.5 | 1.5 | 1.5 |

| Aggregate weighing accuracy (%) | ±2 | ±2 | ±2 | ±2 |

| Cement weighing accuracy (%) | ±1 | ±1 | ±1 | ±1 |

| Water weighing accuracy (%) | ±1 | ±1 | ±1 | ±1 |

| Additive weighing accuracy (%) | ±1 | ±1 | ±1 | ±1 |

| Control system | Panel | Computer | Computer | Computer |

| Total power (kw) | 42 | 46 | 67 | 77.5 |

| Total weight) | 12 | 13 | 14.5 | 26 |

Mobile Concrete Plant for Sale Application

Concrete mixing station is suitable for highway traffic projects, water conservancy and hydropower projects, construction, mining energy projects, municipal emergency projects, etc.

- Whether it is urban construction or rural road reconstruction, concrete mixing station support is required. Large projects can choose YG large concrete portable batch plant, which can produce more than 500 cubic meters per day.

- Small projects are suitable for a small mobile concrete mixing station, which only occupies 20 square meters. In the mobile concrete plant for sale, YG’s equipment can adapt to complex environments such as plateaus and high temperatures, and has performed well in highway repairs, water conservancy projects, and mine construction.

- Small mobile concrete mixing plants have become a popular choice for self-built houses and small bridges in rural areas due to their small footprint and low energy consumption.

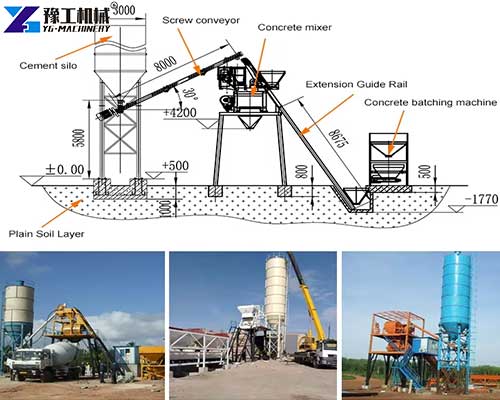

Components of Small Mobile Concrete Mixing Station

The small mobile concrete mixing station produced by YG has complete supporting equipment.

- The automatic feeding equipment has two optional belt conveyors and screw conveyors, which can be matched according to the type of raw materials.

- The precise batching machine supports 3 or 4 kinds of aggregates to be batched at the same time, and the error is controlled within ±1%. 3. The weighing bucket uses a high-precision sensor to display weight data in real time.

- Efficient discharging equipment installation, such as one-line discharging and T-shaped discharging. They have anti-blocking devices to ensure smooth discharge of concrete.

- The storage system includes cement silos, fly ash silos, etc., with capacities ranging from 50 tons to 300 tons to meet different production capacity requirements.

- Control system. All parts of the equipment will be concentrated in the control system. Convenient operation, intelligent and adjustable.

Workflow of Small Mobile Concrete Mixing Plants

The workflow of a concrete portable batch plant is very clear.

- The raw materials enter the storage system through the feeding equipment, and the silo is equipped with a level meter to monitor the surplus in real time.

- The batching machine automatically feeds the materials to the weighing hopper according to the set ratio and stops automatically after reaching the weight.

- The weighed raw materials enter the mixing host, add water and additives, and stir for 30-60 seconds until uniform. 4. Finally, it is transported to the engineering vehicle through the discharging equipment. The whole process is operated by touch screen, and the parameters can be saved with one click, so novices can quickly get started.

Feedback from Mobile Concrete Mixing Station Customers

- A Romanian customer purchased YG’s mobile concrete mixing station for the Danube River Expressway project. The project needs to cross 3 mountain tunnels, with scattered construction sites and narrow mountain roads. The equipment was transported to the site by a small truck and installed in 3 days. Customer feedback: “The equipment is easy to install, works continuously for 12 hours a day, produces 280 cubic meters of C30 concrete, and the strength meets the standard rate of 100%.”

- A Zimbabwean customer purchased a small mobile concrete mixing station for rural school construction. The local power supply is unstable, and the equipment is equipped with a diesel generator. The customer said: “The mixed concrete is used to pour the foundation and walls of the classroom, and the construction of 3 teaching buildings was completed in 30 days. The equipment fuel consumption is only 8 liters per day, which saves a lot of money compared to the budget, and the later maintenance is also simple.” Both mobile concrete mixing stations have won customer recognition.

Features of Concrete Mixing Station

YG’s concrete mixing station has three major selling points.

- Strong portability, tire or track design, the tire model can reach a speed of 50 kilometers per hour, and the track model is suitable for muddy roads.

- Flexible customization, you can choose a large station or a small mobile concrete mixing station according to the scale of the project, and the batching accuracy and mixing speed can be adjusted.

- Affordable price, direct supply from the source factory, 15%-20% lower than the middleman’s quotation. Choose YG for mobile concrete plant for sale, which is more cost-effective.

Mobile Concrete Plant for Sale-YG Machinery

YG has been focusing on the production of various mixing stations for 15 years, including concrete portable batch plants that meet large projects and mobile concrete mixing stations suitable for small projects. The supporting equipment is complete, the feeding equipment has loaders and belt conveyors to choose from, the batching machine supports computer automatic proportioning, and the storage system is equipped with moisture-proof devices. We will first understand your project scale, raw material type, and production capacity requirements, and then recommend supporting equipment. Whether you need a mobile concrete plant for sale or a customized solution, we can meet it. In addition to the first time, we also produce concrete mixers concrete pumps, and concrete mixer and pumps. Click here to consult. YG will customize an exclusive concrete mixing station solution for you to start efficient construction!