The crawler DTH drilling rig innovatively integrates the crawler walking mechanism and the down-the-hole impactor. The crawler is made of high-strength rubber material, which can move freely in complex road conditions such as muddy and steep slopes. The down-the-hole impactor uses high-frequency impact technology and can achieve thousands of impacts per minute. It can quickly break rock formations with relatively high hardness. The equipment is also equipped with an intelligent electronic control system, which can monitor the drilling pressure, speed, and other data in real time through the operation panel, making the drilling operation more accurate and controllable. If you want to drill more conveniently, click to contact us to get the latest quotation!

Hot selling crawler DTH drilling rig model Parameters

| Model | YG412 | YG420B |

| Drilling diameter(mm) | 50~203 | 50~150 |

| Rock hardness | f=6~20 | f=6~20 |

| Drilling depth (m) | 30 | 40 |

| Walking speed(km/h) | 2.5 | 2.5 |

| Gradeability | 30° | 30° |

| Power type | Diesel | Diesel |

| Fuel tank volume(L) | 85 | 85 |

| Hydraulic oil tank volume(L) | 188 | 188 |

| Weight(Kg) | 6300 | 6300 |

| Dimension(mm) | 6600*2110*2500 | 6600*2110*2500 |

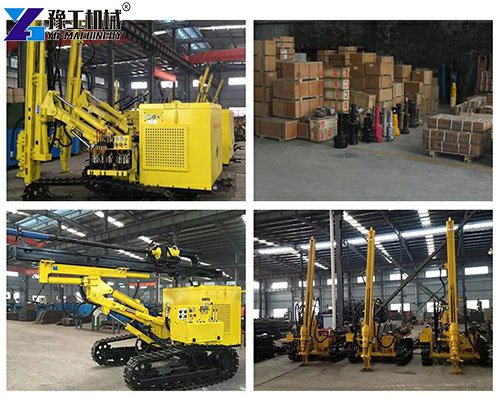

Hot-Selling Models of YG DTH Drilling Machine

- YG412 As a compact crawler down the hole drilling machine, the width of the whole machine is only 2.1 meters, which is suitable for narrow space operations such as urban subway construction and building foundation pit support. It is equipped with a 120 kg-level impactor, which can drill 2.5 km per hour in medium-weathered rock formations, and its efficiency is far higher than that of similar products.

- YG420 is the “power”, equipped with a 200kg high-torque impactor, with a maximum drilling diameter of 150mm and a depth of up to 40 meters. It is particularly suitable for large-scale mining, hydropower engineering foundation drilling, and other large-scale projects. Both devices are equipped with an intelligent fuel consumption monitoring system as standard, which reduces fuel consumption by 15% compared with similar products, and has outstanding cost-effectiveness.

Use of Hydraulic DTH Drilling Machine for Sale

- In the field of mining, the crawler DTH drilling rig is the “main pioneer” of open-pit mines. It can quickly drill blast holes up to tens of meters deep on the hillside, providing precise points for blasting operations.

- In road construction, whether it is the advanced exploration hole for tunnel excavation or the anchor hole for slope protection, down-the-hole drilling rigs can show their skills.

- In water conservancy projects, it can be used for the construction of dam foundation grouting holes, accurately controlling the hole diameter and depth to ensure the grouting quality.

- During geological exploration, the equipment is compatible with various specifications of drilling tools, which can obtain core samples from different strata and provide reliable data support for geological research.

Great Features of Down the Hole Drilling Rigs

- The hydraulic system of down the hole drilling rigs adopts variable piston pump, which can automatically adjust the output power according to the drilling resistance, and has significant energy-saving effect.

- Its crawler chassis is equipped with independent suspension device, which can effectively buffer vibration and extend the service life of the equipment when driving on rugged terrain.

- In terms of operation, the equipment adopts ergonomically designed joystick, and novices can get started after simple training.

- In terms of maintenance, the key components are modularly designed, and no complex tools are required to replace wearing parts. The single maintenance time is shortened by 40%, greatly reducing the downtime cost.

Structure of Crawler down the Hole Drilling Machine

The crawler walking system of crawler DTH drilling rig consists of drive wheels, guide wheels, supporting wheels and crawler chain links. Each component has been specially heat-treated, and the wear resistance is improved by 3 times.

- The hydraulic system includes a power unit, a control valve group and an actuator cylinder, and adopts a dual-circuit design to ensure stable power transmission.

- The drill rod is made of high-strength alloy steel, and the surface is treated with a special coating, which has strong corrosion resistance. It cooperates with the impactor through a quick connection device, and the disassembly and assembly efficiency is increased by 60%.

- In addition, the equipment is also equipped with an automatic lubrication system, which can regularly add lubricating oil to key parts to reduce wear and ensure long-term stable operation of the equipment.

Why Is YG’s Crawler DTH Drilling Rig so Popular?

- As a professional crawler down the hole drilling machine manufacturer with many years of experience in the field of drilling equipment, YG has independently developed core technologies.

- The production workshop adopts a fully automated production line, and each DTH drilling rig must undergo 72 hours of continuous operation testing to ensure zero failure before leaving the factory.

- We provide “nanny-style” after-sales service, respond to global customer needs within 48 hours, and our engineers can remotely assist in solving technical problems.

- There are also great discounts. When you buy the equipment, you will get a full set of wearing parts and operation training courses for free, so that customers can buy with confidence and use with ease.

How to Choose the Right DTH Drilling Rig Model?

- When choosing a DTH drilling rig, the drilling depth is the key. Generally speaking, YG412 can handle shallow hole operations within 30 meters; for deep hole tasks exceeding 30 meters, YG420 is recommended.

- The aperture requirement is also important. Small anchoring projects can choose 80-100mm aperture equipment, while mine blasting holes require models with apertures of more than 120mm.

- In addition, the hardness of the material cannot be ignored. Soft rocks such as limestone have lower equipment requirements, while hard rocks such as quartzite require models equipped with high-power impactors.

Not sure how to choose? Contact our professional team, we will tailor the best procurement plan according to the project budget and construction period requirements, and we can also provide air compressors and dust collectors in one stop to save you procurement costs!

Down-the-Hole Drilling Rig for Sale-YG Machinery

As a professional hydraulic DTH drilling machine for sale manufacturer, YG has been deeply involved in the field of drilling equipment for many years and has strong technical capabilities. Our product line is rich, not only with crawler DTH drilling rigs with excellent performance, but also portable down-the-hole drills to meet the needs of different scenarios. Portable down-the-hole drills are small and easy to move, suitable for small projects and exploration operations; down-the-hole drilling rigs are competent for large and complex projects with their powerful power and flexible maneuverability. Our professional team will have a deep understanding of your project scale, construction environment, and budget, and accurately recommend suitable models. Whether it is large-scale drilling in mining or fine operations in municipal engineering, we can find cost-effective solutions for you. Choosing YG means choosing professionalism and peace of mind. Come and contact us to get exclusive solutions!