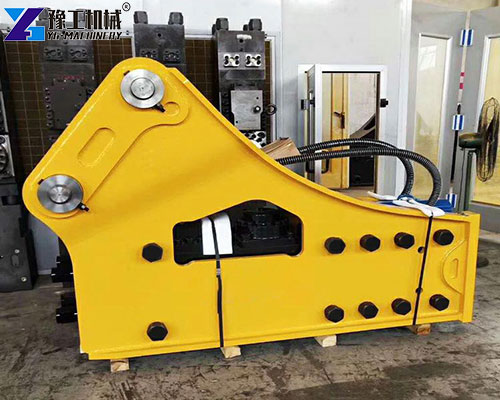

The excavator concrete breaker is also called a hydraulic breaker machine. Through the hydraulic system, it converts the hydraulic energy of the excavator into a high-frequency impact force, striking the brazing rod, and then breaking all kinds of hard materials. Whether it’s demolishing old buildings or mining, it can make a big difference. For example, in urban renewal projects, it can quickly demolish abandoned concrete structures; in mining operations, it can easily break hard rocks. Looking for high-quality excavator concrete breakers! Contact us now!

Excavator concrete breaker parameter

| Model | ChiselDiameter | SuitableCarrierWeight | Main bodyWeight | OperatingPressure | Hydraulic Oil Flow | Blow Frequency | HoseDiameter |

| mm | Ton | kg | Kg/cm 2 | I/min | bpm | inch | |

| YG350 | 35 | 0.5-1 | 40 | 90-120 | 15-25 | 800-1300 | 1/2 |

| YG400 | 40 | 1-3 | 53 | 90-120 | 15-25 | 800-1300 | 1/2 |

| YG450 | 45 | 1.2-3.0 | 67 | 90-120 | 20-30 | 700-1200 | 1/2 |

| YG530 | 53 | 2.5-4.5 | 85 | 90-120 | 25-50 | 600-1100 | 1/2 |

| YG600 | 60 | 2-5 | 140 | 90-120 | 25-50 | 600-1100 | 1/2 |

| YG680 | 68 | 4-7 | 152 | 110-140 | 40-70 | 500-900 | 1/2 |

| YG750 | 75 | 6-9 | 210 | 120-150 | 50-90 | 400-800 | 1/2 |

| YG850 | 85 | 7-14 | 278 | 130-160 | 60-100 | 400-800 | 3/4 |

| YG100 | 100 | 10-15 | 475 | 150-170 | 80-110 | 350-700 | 3/4 |

| YG1250 | 125 | 15-18 | 616 | 150-170 | 80-110 | 350-700 | 3/4 |

| YG1350 | 135 | 16-26 | 846 | 160-180 | 130-150 | 400-800 | 1 |

| YG1400 | 140 | 18-26 | 916 | 160-180 | 120-180 | 350-500 | 1 |

| YG1400A | 140 | 18-26 | 952 | 160-180 | 120-180 | 350-500 | 1 |

| YG1500 | 150 | 27-35 | 1088 | 160-180 | 150-190 | 350-700 | 1 |

| YG1550 | 155 | 28-36 | 1309 | 180-200 | 200-260 | 250-400 | 1-1/4 |

| YG1650 | 165 | 30-40 | 1438 | 180-200 | 200-260 | 250-400 | 1-1/4 |

| YG1650P | 165 | 30-40 | 1586 | 180-200 | 200-260 | 250-380 | 1-1/4 |

| YG1750 | 175 | 35-40 | 1929 | 180-200 | 210-290 | 200-350 | 1-1/4 |

| YG1850 | 185 | 35-45 | 2411 | 190-220 | 220-270 | 200-250 | 1-1/4 |

| YG1990 | 190 | 40-55 | 2626 | 190-220 | 220-290 | 180-200 | 1-1/4 |

| YG2100 | 210 | 60-80 | 3396 | 200-240 | 290-350 | 150-200 | 1-1/4 |

Why is it recommended to use a concrete breaker for mini excavator?

- Double the efficiency: Traditional demolition requires approval and clearing, while the Hydraulic Breaker Machine (HBM) is ready to use right out of the box, increasing the amount of demolition in a single day by 200%.

- Lower cost: No need to purchase additional equipment, directly utilize the existing excavator hydraulic system, and fuel consumption is reduced by 15%-20 %.

- Safety and environmental protection: No risk of blasting flying rocks, dust reduction of 80%, in line with the stringent standards of urban construction.

- Precise control: The operator can adjust the impact strength at any time to avoid accidental damage to the surrounding structure.

Price analysis of the excavator breaker hammer

Price is the focus of customers’ attention, and the pricing of YG Excavator Concrete Breaker follows three main principles:

- Model matching: light hammers are suitable for small excavators, heavy hammers are specially designed for mines, and the price is proportional to the tonnage.

- Material difference: The brazing rod is made of Swedish SSAB steel or domestic common steel; the life span difference is 3-5 times, and the price is naturally different.

- Service value: YG provides a 5-year warranty, free analysis of working conditions, and the cost of long-term use is much lower than miscellaneous products.

Tip: Low-priced products may hide “high fuel consumption, easy oil leakage, expensive maintenance” traps; choose the right brand to save more money.

Attachment crushing hammers’ packing and shipping

We strictly controls the delivery of products:

- Anti-rust treatment: the crushing hammer cylinder is coated with anti-rust oil, and the brazing rod is covered with a plastic protective sleeve to avoid corrosion by sea.

- Customized wooden crate: customized fumigation-free wooden crate according to the size of the equipment, filled with EPE cushioning material inside to prevent collision and shock.

- Real-time tracking: cooperating with a famous freight forwarder, providing container number and shipping date information, which can provide you with factual transportation status.

- Arrival inspection: After the customer opens the box, YG engineers will guide the inspection by video to ensure that the brazing rod is not bent and the hydraulic pipe is not broken.

YG: A manufacturer specializing in hydraulic breaker machines

YG is a professional manufacturer that has been deeply involved in the field of tool breakers for 15 years, and has always taken “efficient demolition solutions” as its core competitiveness. Our excavator concrete breaker, with its independently developed hydraulic impact system, achieves precise control of impact energy with an error of less than ±3%, and is compatible with global mainstream excavator models such as Caterpillar and Komatsu. We provide “working condition customization” services, which can adjust the equipment weight, impact frequency, and noise reduction design according to scenarios such as hard rock in mines and urban demolition.