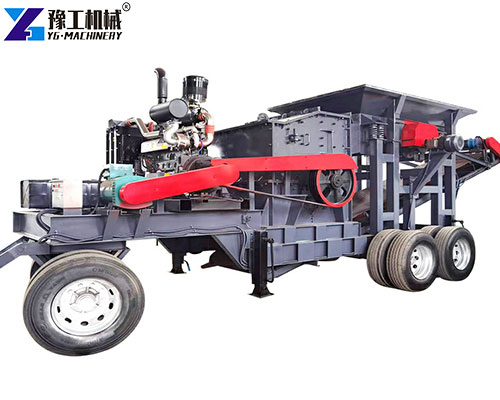

Mobile rock crusher is an efficient crushing tool in modern engineering and construction. It breaks the limitations of traditional fixed crushing equipment and integrates crushing, screening, and other functions on a movable chassis. Whether it is a tire-type flexible transfer or a crawler-type adaptable to complex terrain, it can easily achieve rapid equipment migration and reduce site restrictions. Its working principle is based on advanced crushing technology. Mobile jaw crusher is a universal primary crushing equipment. The equipment can adjust the discharge size according to its own needs. Click to get a powerful mobile crushing station plan and price!

Mobile Rock Crusher Parameters

| Model | 800×800 | 800×1000 | 1000×1200 | 1200×1200 | 1200×1500 | 1400×1600 |

| Motor Power | 90kw×4G | 110kw×4G | 132kw×4G | 160kw×4G | 185kw×4G | 250kw×4G |

| Diesel Power | 195HP | 195HP | 260HP | 330HP | 330HP | 400HP |

| Hopper | 3500*1800*8mm | 3600*2200*8mm | 3600*2200*8mm | 3800*2200*8mm | 3800*2200*8mm | 4000*2400*10mm |

| Hammerhead Weight | 15kg | 15kg | 20kg | 36kg | 36kg | 55kg |

| Total Weight | 10t | 12.5t | 14t | 19t | 21t | 26t |

| Belt | 7×0.8m | 8×0.8m | 8×1m | 8×1m | 8×1m | 9×1m |

| Belt Conveyor Power | 5.5kw | 5.5kw | 7.5kw | 7.5kw | 7.5kw | 7.5kw |

| Tyre Model×Number | 1100×8pcs | 1100×8pcs | 1100×8pcs | 1000×12pcs | 1100×12pcs | 1100×12pcs |

| Sand Capacity | 30t | 45t | 55t | 65t | 80t | 100t |

| Stone Capacity | 50t | 70t | 80t | 90t | 120t | 180t |

| Overall Size | 10*2.8*3.5m | 11*2.8*3.5m | 11.5*2.8*3.5m | 12*3*3.6m | 12*3*3.6m | 13*3.2*3.7m |

Popular Application Scenarios of Mobile Concrete Crusher

- In the United States, there are a large number of building demolition projects every year, and many builders choose to use a mobile concrete crusher to deal with the waste concrete generated by demolition. Like the old town renovation project in Manhattan, New York, 3 mobile concrete crushers entered the construction site and can process more than 2,000 tons of waste concrete every day. The crushed aggregate is directly used for the paving of the surrounding road base, saving more than 40% of the transportation and raw material procurement costs.

- Canada is rich in mining resources, and transportation is inconvenient in remote mining areas. Local mining companies prefer portable jaw crushers, whose mobility allows them to easily reach mining areas with complex terrain. For example, in gold mining in the Yukon, mobile rock crushers crush ore on site, reducing the transportation volume of raw ore by 70%, greatly reducing transportation costs, and improving mining efficiency.

- Australia has many road construction projects and tight construction schedules. Mini stone crusher plant can crush stones into suitable specifications on site to speed up road paving. In the Sydney-Melbourne highway expansion project, 10 rock crushers form a crushing production line. 5,000 cubic meters of qualified stone are produced every day, which shortens the construction period by nearly one-third compared to traditional fixed crushing equipment.

What Materials Can a Portable Jaw Crusher Handle?

- Mobile crushing station is an “all-around player”! Whether it is hard stone such as granite and basalt with a Mohs hardness of 7, or medium-hard materials such as limestone and gypsum with a slightly lower hardness, it can easily handle it.

- It is also easy to handle construction waste, slag, and other waste. The equipment will crush them and process them into recycled aggregates, turning waste into treasure, saving resources, and being environmentally friendly. Taking construction waste as an example, a mobile rock crusher can crush bricks and concrete blocks into aggregates of different sizes of 0-40mm. These aggregates can be used to produce environmentally friendly bricks, roadbed fillers, etc., to achieve resource recycling.

YG Hot-Selling Mini Stone Crusher Plant Model

1. 400*600 Jaw Crusher

400*600 jaw crusher is the favorite of many customers. It is compact and mobile, and can be easily used in small projects. Its crushing ratio is as high as 4-6, and the machine output is 16-64t/h. The discharge particle size is evenly adjustable between 40-100mm, and can be adjusted as needed. The price is 15%-20% lower than that of similar equipment, with super high cost performance and fast return on investment. It is right to use it for small-scale mining and rural road construction! A small mine in Yunnan once purchased this model and recovered the equipment cost through efficient production in 3 months.

2. 800*800 Mobile Box Crusher

800*800 mobile box crusher has a large processing capacity, with an output of 60-80 tons per hour and high crushing efficiency, suitable for large stone factories and quarries. Equipped with an advanced screening system, it can be formed in one time to reduce the cost of secondary processing. It is easy to move and easy to transfer operations, which is a good helper for large-scale crushing projects. After a large quarry in Xinjiang introduced this equipment, its production efficiency increased by 35%, and its annual income increased by more than one million yuan.

Why Choose YG’s Portable Jaw Crusher?

YG is a professional mobile rock crusher manufacturer in the industry. Mobile crushing stations are crucial in modern engineering and construction. YG’s equipment is sold in more than 50 countries around the world, and we have loyal customers in the United States, Canada, and Australia. The key components of our machines are made of high-strength alloy steel, which is wear-resistant and durable, and has a service life that is 3-5 years longer than ordinary equipment. The discharge size of the machine can be precisely adjusted to meet the needs of different projects. We can also provide customized solutions based on your needs. YG’s regular orders can be shipped in 3-5 days, allowing you to start work and make profits faster. YG also provides concrete delivery pumps, concrete mixers, mortar sprayers, concrete mixing delivery pumps, and other related equipment!