Excavator attachment pile breaker is a special equipment installed on the excavator, which is specially used to break concrete piles. It consists of multiple crushing modules, which can be flexibly adjusted according to the diameter of the pile body, and has strong adaptability. Whether it is a hard reinforced concrete pile or an ordinary concrete pile, it can easily handle it. The excavator pile breaker can quickly handle piles of various specifications, making pile breaking easier. If you are looking for an efficient pile breaking solution, you might as well learn about this equipment.

Pile Breaker Technical Parameter

| Module Number | PCS | 4 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| Combination of the total weight | KG | 1600 | 2640 | 2970 | 3300 | 3630 | 3960 | 4290 | 4620 | 4950 | 5280 | 5610 | 5940 |

| Pile diameter range | mm | 400-600 | 600-800 | 800-1000 | 1000-1150 | 1150-1300 | 1300-1500 | 1500-1650 | 1650-1800 | 1800-1970 | 1970-2200 | 2200-2360 | 2360-2500 |

| Hydraulic excavator | T | 20T-30T | 30T-40T | Hydraulic system/pump station | |||||||||

| Max.Thrust | 300KN | Max.Cylinder required | 20L/min | Machinery Tonnage | ≥20T | Location pinΦ35 | |||||||

| Max.Cylinder Trip | 300mm | Chisel diameter | 110mm | Single module weight | 335KG | ||||||||

| Max.Cylinder Pressure | 300MPa | Max.Hoist Capacity | ≤500mm | Singlemodulesize | 1015*865*340mm | ||||||||

Concrete Pile Crusher Application Engineering

- In building demolition projects, concrete piles are left after the demolition of old buildings. It can be quickly broken to make room for new building construction and save a lot of site cleaning time.

- In road expansion projects, the old pile foundations under the original road will hinder the construction of new roads. It can accurately break these pile foundations without affecting the surrounding road structure.

- A concrete pile crusher has similar functions to it and is often used in municipal engineering. For example, when building urban subways, the abandoned concrete piles encountered along the line can be efficiently handled by a concrete pile crusher to ensure the smooth progress of subway construction.

- In the community renovation project, it can also play an important role in removing old underground piles.

- The hydraulic pile cutter is also a good helper in the project. In the later stage of bridge construction, the excess pile foundation at the bottom of the pier needs to be cut off to a specified height, and the hydraulic pile cutter can operate accurately. The cut is smooth to ensure the stability of the bridge structure.

- In port construction, it can also efficiently complete the underwater pile foundation treatment of the dock and adapt to the complex underwater environment.

Application and Feedback from Romanian Hydraulic Pile Breaker Customers

Many construction companies in Romania are using concrete pile crushers with excavator attachments.

- A customer was responsible for a highway expansion project. In the past, he used manual pneumatic picks to break piles, and could handle a maximum of 10 piles a day. After using concrete pile crushers, he could handle more than 50 piles a day, which increased work efficiency several times and completed the construction period ahead of schedule.

- There are also customer feedback that their construction sites are mostly in mountainous areas, and the equipment transportation and use environment are poor, but the hydraulic pile cutter is durable and has no failures in three consecutive months of work, which greatly reduces maintenance costs. They have also used pile cutter. When dealing with concrete piles with a diameter of 1.2 meters, they find the operation simple. Even novices can quickly get started. Moreover, the residue particles of the broken piles are small and easy to transport by truck, which improves the cleanliness of the construction site.

Cost-Benefit Analysis of the Concrete Pile Cutting Machine

- Using a pile breaker with excavator attachments can greatly reduce labor input. In the past, 10 workers were required to work in shifts to break piles. Now, one device plus two operators are enough, and labor wages are directly reduced by 80%. The daily fuel consumption of the equipment is lower than the electricity and consumables costs of manual tools, and the daily expenses are lower.

- In the long run, the service life of the equipment can reach more than 5 years, during which only the wearing parts need to be replaced regularly, and the maintenance cost is low. Although there is an initial investment in equipment, compared with the long-term labor and consumables expenses, it can be recovered in less than a year, and it is a net profit afterwards.

- When using it to break piles, the steel bars after the pile body is broken can be recycled and reused, which improves resource utilization and brings additional benefits.

Working Principle of the Hydraulic Concrete Pile Cutter

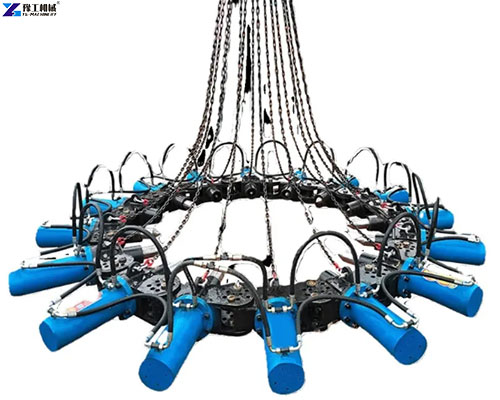

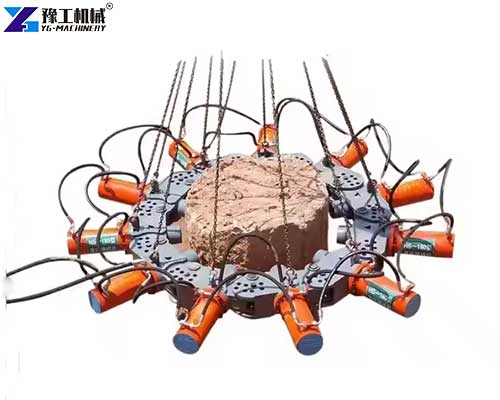

The pile breaker is driven by the hydraulic system of the excavator. Its multiple breakers are distributed in a ring. When working, the breakers are first placed on the top of the concrete pile, and then the hydraulic power is used to push the breakers into the pile body. The tip of the breaker will smash the surface of the pile body, and then gradually move downward. Then it will continue to squeeze and hit the pile body until the entire pile body is broken into small pieces.

The Importance of Pile Breakers for Excavator Attachments

- Hydraulic concrete pile cutters are very important in engineering construction. It can avoid the safety hazards of manual pile breaking, which is prone to splashing and injuring people. When the equipment is operating, the operator is in the excavator, away from the dangerous area, and the accident rate is almost zero.

- It can also protect the surrounding environment. The crushing process has little vibration and low noise. Construction in residential areas will not affect the lives of residents and reduce complaints.

Without it, pile-breaking work will become slow, delay the construction period, increase costs, and may also affect the quality of the project due to irregular construction. Therefore, it is an indispensable and important equipment in modern engineering.

Hydraulic Pile Cutter for Sale-YG Machinery

YG is a high-quality excavator attachment pile breaker manufacturer. It provides a full range of hydraulic concrete pile cutter models, from handling thin piles with a diameter of 30 cm to thick piles with a diameter of 2 meters, and there is suitable equipment to deal with it. Models can also be customized according to special customer needs. The equipment’s breaker hammer is made of high-strength alloy material with high hardness and strong wear resistance, and its service life is 30% longer than similar products.

YG also provides comprehensive after-sales service! After-sales response is fast, and solutions can be provided within 24 hours if there is a problem with the equipment. We also provide other excavator attachments, such as hydraulic shears, breaker hammers, rock saws, crushing buckets,etc. If you want to make pile breaking easier and more efficient, come and consult YG’s excavator attachment hydraulic concrete pile cutter!