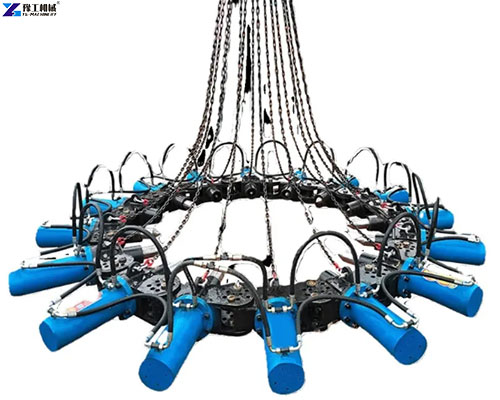

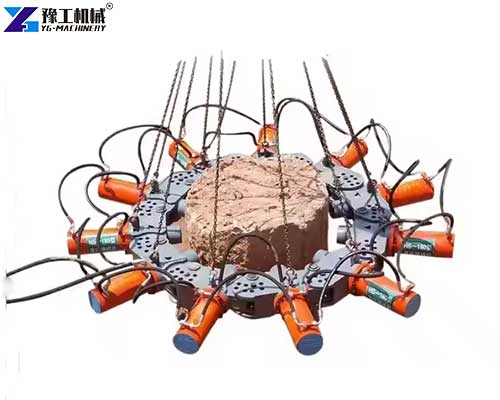

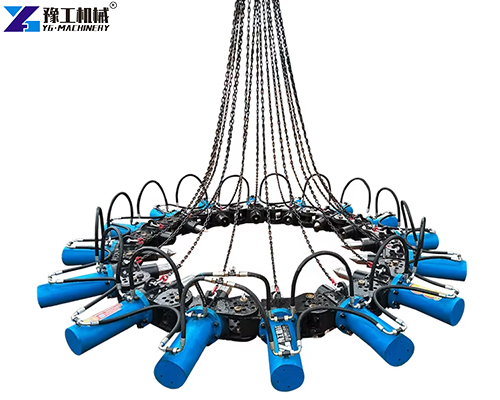

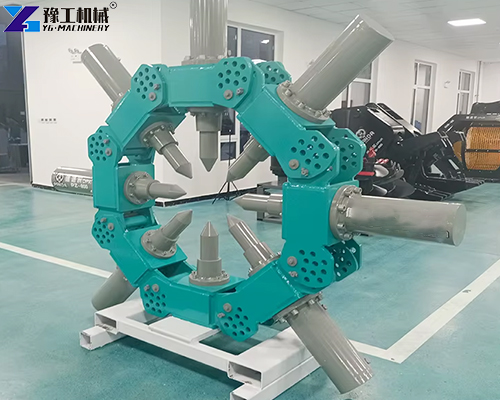

The pile breaker machine, resembling a circular “pliers, is constructed entirely of high-strength alloy steel for durability. It features multiple hydraulic hammers evenly distributed throughout the ring structure, firmly gripping the concrete pile and ensuring even force distribution. Once activated, the hammers continuously strike the pile at a set frequency, gradually breaking it from the top until the desired depth is reached. YG’s pile breaker machines are available in a variety of sizes, ranging from small models capable of easily breaking piles up to 30 cm in diameter to large models capable of handling piles over 1 meter in height. Click the button below to inquire about the right pile breaker for you!

Pile Breaker Machine Parameter

| Module Number | PCS | 4 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| A combination of the total weight | KG | 1600 | 2640 | 2970 | 3300 | 3630 | 3960 | 4290 | 4620 | 4950 | 5280 | 5610 | 5940 |

| Pile diameter range | mm | 400-600 | 600-800 | 800-1000 | 1000-1150 | 1150-1300 | 1300-1500 | 1500-1650 | 1650-1800 | 1800-1970 | 1970-2200 | 2200-2360 | 2360-2500 |

| Hydraulic excavator | T | 20T-30T | 30T-40T | Hydraulic system/pump station | |||||||||

| Max.Thrust | 300KN | Max.

Cylinder required | 20L/min | Machinery Tonnage | ≥20T | Location pin

Φ35 | |||||||

| Max.

Cylinder Trip | 300mm | Chisel diameter | 110mm | Single

module weight | 335KG | ||||||||

| Max.

Cylinder Pressure | 300MPa | Max.

Hoist Capacity | ≤500mm | Single

module size | 1015*865*340mm | ||||||||

Key Points for Using a Pile Cutter for Sale

- Before using the pile breaker machine, carefully check the hydraulic hoses for leaks, ensure the joints are secure, and ensure the hydraulic oil level is sufficient.

- Then, place the machine firmly on top of the pile and adjust the position using the adjustment mechanism to ensure each hammer is firmly against the pile to avoid uneven force distribution. 3. When starting, run the machine at low speed for one minute to check that all parts are operating normally and for any unusual noises.

- During the crushing process, constantly monitor the pile for changes. If you encounter hard rocks or rebar, slow down the machine to prevent damage.

- After the operation, clean any concrete debris from the machine and lubricate all moving parts to effectively extend its service life.

Benefits of Hydraulic Pile Breaking Machines in Construction Projects

- Hydraulic pile breaking machines are powered by hydraulics, resulting in low noise levels and minimal disruption to the daily lives of surrounding residents. They are particularly suitable for construction near residential areas.

- The pile fragments they crush are uniform in size, greatly facilitating subsequent cleanup and transportation, and reducing site usage.

- With these machines, pile breaking tasks that once took five people a day can now be easily completed by one person in half a day, significantly saving both manpower and time. Engineering

- Using this machine not only significantly shortens construction timelines but also reduces labor costs, improves overall construction efficiency, and maximizes project profitability.

Environmental Benefits of the Hydraulic Pile Cutter

- The hydraulic pile crusher is equipped with a dedicated dust suppression device, which eliminates excessive dust generation, preventing air pollution and protecting the health of construction workers.

- Its hydraulic system utilizes advanced sealing technology, ensuring a tight seal and preventing oil leakage, thus preventing soil contamination.

- Crushed pile fragments can be directly recycled and reused. After simple processing, they can be made into construction aggregate, reducing the generation of construction waste.

- Compared to traditional crushing methods, using a pile breaker neither pollutes the air nor wastes resources, fully complying with current environmental protection requirements and making it an ideal choice for green construction.

Environmental Benefits of the Hydraulic Pile Cutter

Last year, our pile cutter for sale was sold to a large-scale construction project in Saudi Arabia. This project is a key local project with extremely high construction efficiency requirements. The piles there are made of high-strength concrete, making them very hard. The local construction team used traditional crushing methods, which were not only time-consuming but also ineffective, seriously impacting the project’s progress. With our equipment, they can crush over 50 piles per day, three times faster than before. Furthermore, the equipment continues to operate reliably in Saudi Arabia’s hot and dry environment, with a very low failure rate. The project manager has repeatedly praised the equipment for its efficiency and durability, helping them complete the project ahead of schedule and earning praise from the local government.

Pile Breaker Machine for Sale-YG Machinery

YG pile breakers are high-quality and efficient. Crafted using advanced production technology and high-quality raw materials, they offer stable and reliable performance. We also provide comprehensive after-sales service. No matter where you are in the world, we ensure timely delivery and provide on-site guidance from professional technicians for operation and maintenance. Our pile breakers have been sold to Brazil, Germany, France, the UK, Africa, Ghana, and other countries. YG Machinery also manufactures a wide range of other equipment, including solar-powered pile drivers, guardrail pile drivers, rotary drilling rigs, helical pile drivers, and other related equipment! If you’re looking for efficient pile breaking equipment, contact us now; you won’t be disappointed.