A pile driver is a large piece of construction machinery whose core function is to drive wooden, concrete, or steel piles into the soil. These piles distribute the weight of buildings and prevent them from sinking, making them crucial equipment for ensuring construction safety. There are many different types of pile drivers, classified by their operating method: vibration, impact, and static pressure. Vibration uses high-frequency vibrations to loosen the soil, facilitating the sinking of the pile; impact uses a heavy hammer to repeatedly strike the pile, driving it into the ground. Different types of pile drivers are suitable for different construction environments.

Piling machine for sale parameter

| Model | YGLD-13 | YGLD-15 | YGLS-16 | YGLD–20 |

| Max.Drilling Diameter | 1000mm | 1600mm | 1500mm | 1600mm |

| Max.Drilling Depth | 13m | 15m | 16m | 20m |

| Max. Rotary torque | 50KN.m | 45kN .m | 46KN.m | 36KN.m |

| Rotary angle | 360° | 180° | 180° | 360° |

| Rotary speed | 10-45r/min | 17-45r/min | 20-46r/min | 22-43r/min |

| Dimension(m) | 3.1×1.92×3.5m | 6.8×2.27×3.2m | 10 x 2.3x 3.2 m | 9.5×2.6×3.5m |

| Weight | 9ton | 13 ton | 11 ton | 17.8 ton |

Applications of Pile Drivers

- Pile drivers have a wide range of applications and are ubiquitous in the construction industry. In cities, pile drivers are used to lay solid foundations for high-rise residential and commercial buildings, ensuring their stability.

- In the construction of bridges across rivers and streams, pile drivers are responsible for laying the foundations for bridge piers, protecting them from the pressure of water and vehicles.

- In port construction, they help build the support structures of docks to accommodate ships docking and cargo loading and unloading. 4. It can even be found in smaller projects, such as rural housing construction and road repairs.

- Some pile driver models are compact, making them suitable for use in confined spaces, further expanding their application range.

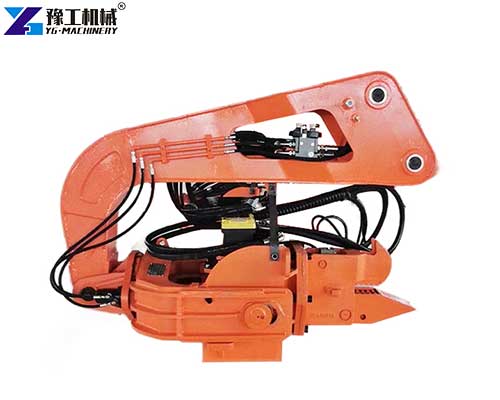

Features of the YG Pile Driver

- The YG pile driver boasts numerous advantages in design and manufacturing, earning it widespread acclaim. Equipped with a powerful engine, it delivers ample power, easily tackling various hard soils and improving construction efficiency.

- The control system is simple, with buttons and levers strategically arranged. Even novice operators can quickly master the system after brief training, reducing learning curves.

- It also prioritizes fuel economy, effectively reducing fuel consumption while maintaining power, saving users significant fuel costs.

- Furthermore, the YG pile driver offers high compatibility, adapting to a variety of pile materials and specifications to meet the needs of diverse projects.

- Safety is also a top priority, with comprehensive protective features such as a protective cover and emergency brake button to ensure operator safety.

How a rotary drilling rigs Works

The operating steps of a pile driver are simple and clear. The operator first moves the machine to the piling location and adjusts the level and angle. Then, they secure the pile and align it with the driving point. The power system then activates, applying force to the pile through impact, vibration, or static pressure, allowing it to slowly sink into the ground. During this process, sensors monitor the verticality and depth of the pile, allowing the operator to make timely adjustments. After a pile is driven, the machine moves to the next location and the process repeats.

Pile Driver Buying Guide

When choosing a pile driver, you need to consider several factors to select the most suitable equipment. 1. First, determine the scale and requirements of the project. For small projects, such as rural housing construction, a small or medium-sized pile driver is sufficient. Large projects, such as bridge construction, require high-powered, heavy-duty equipment.

- Understand the soil type at the construction site. Soft soils require less demanding equipment, while hard soils or rock formations require more powerful and stable equipment. Rotary drilling rigs, for example, are well-suited for these complex geologies.

- Also pay attention to parameters such as the equipment’s power, fuel consumption, and maintenance costs. Power determines construction capacity, while fuel consumption and maintenance costs affect long-term economical use.

- Be sure to choose a manufacturer with comprehensive after-sales service. YG pile drivers excel in this area, offering timely repairs and spare parts.

How to operate a Piling machine?

Pile driver operation must follow standard procedures.

- Before starting, check the fuel and engine oil levels, ensure that component connections are secure, and that the system is functioning properly. Then, start the engine and allow it to idle for a few minutes to warm up.

- Then, move the machine to the piling location, adjust the machine body, and secure the pile.

- Start the piling function slowly during operation, observing the pile sinking and the machine’s operation, and avoid applying excessive force.

- Be aware of the surrounding environment during operation and keep unauthorized personnel away.

- Stop the machine and investigate any abnormalities. After work, shut down the engine, clean the machine, and perform proper lubrication and maintenance.

Piling machine for sale-YG Machinery

As a professional pile driver manufacturer, YG boasts years of production experience and advanced technical capabilities. We offer a wide range of pile driver models, including small and large machines suitable for different projects, and can also customize them to meet specific customer needs. To ensure optimal use of our equipment, YG provides professional operator training and comprehensive after-sales service, offering prompt response for installation, repairs, and parts replacement. Numerous customers who have used YG pile drivers have highly praised their reliability and durability. We also produce rotary drilling rigs, guardrail pile drivers, solar pile drivers, and other related products! If you need a pile driver for sale, choosing YG means you’re choosing peace of mind and efficiency. Feel free to contact us for inquiries and orders!