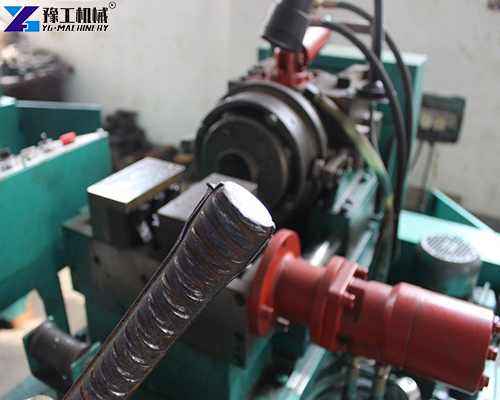

A rebar roughing machine is a specialized device for strengthening rebar ends. Its workflow is clear: First, a high-frequency heating device heats the rebar ends to the desired temperature, making them pliable and easily shaped. Next, the machine’s mold rapidly applies pressure to the heated ends, thickening and densifying them. The treated rebar ends have a larger diameter and increased strength. Its compact size allows for easy placement on construction sites or in processing workshops. Click the button to find the right rebar roughing machine!

Rebar Upset Forging Machine Parameter

| Model | YGDC-40S | YGDC-40D |

| Upsetting Range | 12-32mm | 12-32mm |

| Upsetting Force | 2036KN | 3000KN |

| Cylinder diameter | 220mm | 220mm |

| Motor Power | 4kw | 7.5kw |

| Voltage | 380V 50HZ | 380V 50HZ |

| Oil Pump Pressure | 80Mpa | 31.5Mpa |

| Max. Flow | 5.42L/min | 4.0L/min |

| Upsetting Length | >3.5cm | >3.5cm |

| Increase Size | 3-5mm | 3-5mm |

| Work Efficiency | 15-20s/pieces | 15s/pieces |

| Packing Size | 1020×500×965mm | 1300×830×1350mm |

| Weight | 560kg | 1000kg |

What Types of Rebar Can a Steel Bar Upsetting Machine Handle?

- The rebar roughing machine has a wide processing range and can handle nearly all common construction rebar. It can easily handle hot-rolled ribbed rebar commonly used on construction sites, such as HRB335, HRB400, and HRB500.

- It can accurately process diameters from thin 12mm rebar to thick 40mm rebar. It can handle the 16mm and 20mm rebar commonly used in house construction, as well as the 25mm and 32mm rebar used in bridge construction.

- Furthermore, some special steel materials that meet processing requirements can also be roughened. Both round and ribbed steel bars can be roughened to a qualified end.

Stel Bar Rebar Upsetter Customer Feedback

- Canada: “The construction site previously used traditional methods to process rebar ends, which was slow and tiring, and we couldn’t produce much in a day. After using this rebar roughing machine, our efficiency has increased several times. Two people used to process 50 bars a day, but now one person can process 200. The roughing is excellent, and the connections are secure. It’s a steal!” – John, Construction Manager

- Spain: “The factory previously used other brands, but they often broke down or lacked precision. Switching to the YG machine has eliminated all the problems. The machine operates stably and requires minimal maintenance. The machine produces consistent ends that meet construction standards. It’s easy to operate, and new workers can operate it independently after just two days of training.” – Maria, Factory Owner

- Brazil: “The project was under a tight deadline, and rebar processing was crucial. This machine has been a huge help, processing quickly and reducing waste. Manual processing often resulted in rework due to dimensional issues, but now there’s almost no rework, allowing us to complete the project two weeks ahead of schedule. Thank you so much!” – Carlos, Engineer

4 Features of the Yg Rebar Upsetting Machine

- YG The rebar roughing machine offers many practical features. Its advanced heating system quickly and evenly heats the ends of the rebar, ensuring consistent strength after processing, without any areas that are too hard or too soft.

- The molds are made of high-strength materials, are wear-resistant, durable, and easy to replace. One set of molds can process multiple rebars, reducing consumable costs.

- The user-friendly control panel features clear buttons and a display, making it easy for workers to understand. The simple operation steps make it easy for even low-educated workers to learn quickly.

- The machine body is constructed of high-quality steel, providing a stable structure. It operates with low vibration and noise, minimizing impact on the work environment, and is energy-efficient.

How Does the Steel Bar Upsetter Help Workers Improve Their Efficiency?

- The rebar roughing machine significantly improves worker efficiency. Traditional methods, such as hammering, were laborious and slow, and a single worker could only process a few dozen rebars a day.

- With this machine, workers simply place the rebar into the machine and press a button. The machine automatically completes the heating and extrusion processes, processing a single rebar in just a few seconds. A single worker can process hundreds of bars per day, increasing efficiency severalfold.

- The machine’s high precision ensures few defective products, eliminating the need for repairs or rework, saving workers significant time. Easy operation minimizes physical exertion, allowing for extended periods of efficient work, accelerating progress, and reducing labor costs.

Rebar Upsetting Machine for Sale-YG Machinery

YG has specialized in the production of rebar roughing machines for over a decade and is an experienced manufacturer in the industry. Our dedicated R&D team continuously improves machine performance based on actual construction site needs. Our production workshop maintains a strict quality control system, meticulously inspecting every step, from raw material procurement to component processing and complete machine assembly, to ensure the highest quality machines before they leave the factory. We also offer comprehensive after-sales service. If you encounter any issues with the machine, please contact us online 24 hours a day. We also provide detailed instructions and operator training for ease of use. In addition, we also produce rebar straightening and cutting machines, and CNC hoop bending machines! For efficient and worry-free rebar processing, contact us for more information.