The rubber tire shredder uses advanced technological processes to decompose whole tires into uniform rubber blocks, laying a solid foundation for subsequent recycling and reuse. Choosing the right rubber shredder machine not only improves processing efficiency but also creates significant economic benefits. Welcome to contact our professional team for more product information!【WhatsApp/WeChat/Phone】+86 13837122632

Rubber Tire Shredder Parameters

| Model | YG-3 | YG-6 | YG-10 | YG-16 | YGL-16 | YG-30 |

| Capacity | 1-3t/d | 4-6t/d | 8-10t/d | 12-16t/d | 8t/d (only for rubber powder) | 30-35t/d |

| Working Process | Batch | Batch | Batch | Batch | Semi-continuous | Fully continuous |

| Reactor Size | φ1400*4900mm | φ2200*6000mm | φ2600*6600mm | φ2800*7100mm | φ2800*7100mm | φ1800*18500mm |

| Land (L*W*H) | 18m*4.2m*6m | 30m*12m*8m | 30m*13m*8m | 33m*13m*8m | 33m*13m*8m | 70m*20m*10m |

| Power | 16.65kw | 37.85kw | 44.3kw | 55.6kw | 55.6kw | 256kw |

| Burner | 2*200,000 kcal | 2*300,000 kcal | 2*300,000 kcal | 2*400,000 kcal | 2*400,000 kcal | 2.5 million kcal per set |

| Total Weight of Shipped Materials | About 18t | About 24.5t | About 28t | About 34.5t | About 34.5t | About 150t |

| Noise (dB) | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 |

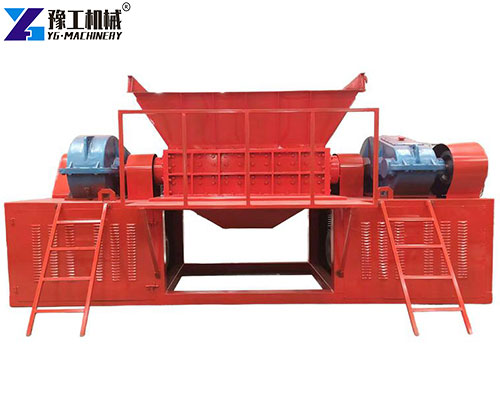

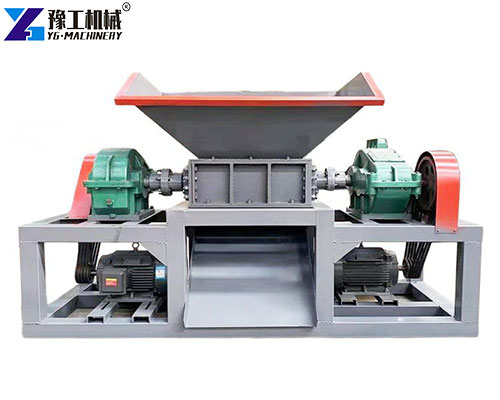

Advantages of Rubber Tire Shredder

• Precision cutter system: The blades are forged, quenched, annealed, tempered, and heat-insulated, then precisely cut with CNC wire cutting technology. This ensures accurate dimensions and excellent wear resistance, which is the core guarantee of the high efficiency of the rubber tire shredder.

• Enhanced transmission design: The coupling of the transmission components is made through a forging process, featuring high density and low failure rate. It effectively protects the main shaft and reducer, ensuring long-term stable operation of the equipment.

• Heavy-duty housing structure: The cast-steel housing thickness exceeds 60mm, fixed by double rows of screws to ensure the equipment remains deformation-free under heavy-duty working conditions, providing a solid operating foundation for the rubber shredder machine.

• High-efficiency reduction device: The reducer adopts a steel plate welded shell, thickened output shaft, and dual keyway design, ensuring large torque, excellent stability, and a significantly extended service life.

• Precision bearing system: The integrated cast-steel bearing seat effectively secures the bearing housing, protecting the bearings and ensuring smooth operation at high speeds while minimizing maintenance requirements.

Wide Application Fields

• Tire recycling: Professionally handles various car tires, truck tires, and construction machinery tires, ensuring efficient processing and uniform output size suitable for industrial reuse.

• Rubber powder production line: Specific models such as YGL-16 are optimized for rubber powder production, achieving fine particle sizes and consistent quality for secondary manufacturing applications.

• Comprehensive recycling: The processed rubber blocks can be used in rubber products, modified asphalt, sports flooring, and other eco-friendly materials, promoting sustainable resource utilization..

Successful Case Studies

• Texas, USA – Tire recycling project

A tire recycling enterprise in Texas introduced two YG-16 model rubber crusher machine units to process the large volume of waste tires generated daily in the region. The client highly valued the equipment’s fully automated control system and stable processing capacity. After six months of stable operation, the two rubber crusher machine units have successfully processed over 2,800 tons of waste tires, producing uniform rubber granules directly supplied to local rubber product manufacturers.

• Barcelona, Spain – Environmental project

An environmental technology company in Spain selected the YG-10 model rubber tire shredder machine for its rubber recycling plant located in Barcelona. The client mainly processes car and motorcycle tires and required the equipment to meet Europe’s strict noise and emission standards. The rubber tire shredder machine, with its ≤60dB low-noise design and high energy efficiency, perfectly met the client’s environmental requirements. Within four months of operation, the equipment steadily processed over 1,200 tons of tires, helping the client successfully expand into the local rubber granule market.

Choose YG Machinery

The rubber tire shredder machine from YG Machinery is known for its efficiency, stability, and durability. It is widely used in the recycling and reuse of tires and rubber products. If you are looking for a cost-effective rubber crusher machine, YG will be your most reliable partner.【WhatsApp/WeChat/Phone】+86 13837122632