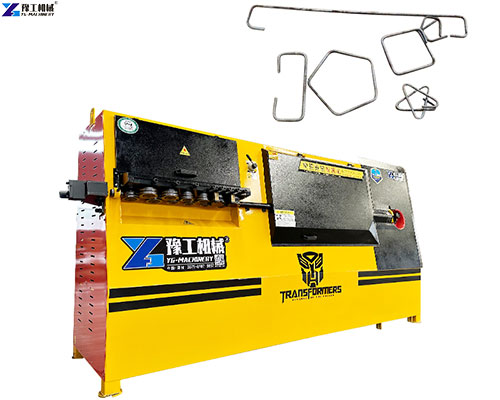

Stirrup bending machine is the core equipment for efficient processing of rebar in the construction industry, specializing in the rapid bending of straight bars into standard shapes such as hoops, frame bars, etc., which is widely used in housing construction, bridges, tunnels, and other projects. The equipment adopts a numerical control system or mechanical transmission technology, through the preset program or manual operation, to achieve accurate bending, adjustable angle, and arc, to meet the diversified needs of the construction.YG also provides steel bar straightening and cutting machines, steel bar bending machines, steel bar dunnage machines, steel bar rolling machines, and other reinforcing bar equipment! Contact us to get the desired factory price for rebar handling equipment!

Stirrup Bending Machine Parameter

| Model | YG-1 | YG-2 | YG-3 | YG-4 |

| Single wire(mm) | Round steel 4-10mmDeformed steel bar 4-8mm | Round steel 4-12mm Deformed steel bar 4-10mm | Round steel 5-14mm Deformed steel bar 5-12mm | Round steel 4-12mm Deformed steel bar 4-10mm |

| Double wire(mm) | Round steel 4-6mm Deformed steel bar 4-6mm | Round steel 4-8mmDeformed steel bar4-8mm | Round steel 5-10mm Deformed steel bar 5-10mm | Round steel 4-8mm Deformed steel bar 4-8mm |

| Max bending angle | ±180° | ±180° | ±180° | ±180° |

| Center pin diameter | 16、18、20 | 16、18、20 | / | 16、18、20 |

| Maximum towing speed | 60m/min | 60m/min | 110m/min | 110m/min |

| Maximum bending speed | 800°/sec | 800°/sec | 1000°/sec | 800°/sec |

| Machine size | 2600*800*1700mm | 3280*1000*1700mm | 3850*1200*2200mm | 3660*1110*1700mm |

| Device color | Yellow(customized) | Yellow(customized) | Yellow(customized) | Yellow(customized) |

| Pieces Processed | ≤2 | ≤2 | ≤2 | ≤2 |

| Air circuit system pressure | ≥0.8mpa | ≥0.8mpa | / | ≥0.8mpa |

| Total Power | 14kw | 20kw | 32kw | 23.5kw |

| Working temperature | -5°C~40° | -5°C~40° | -5°C~40° | -5°C~40° |

| Length accuracy | ±1mm | ±1mm | ±1mm | ±1mm |

| Angle accuracy | ±1° | ±1° | ±1° | ±1° |

| Average power | 4.5KW/h | 5KW/h | 5KW/h | 5KW/h |

| Total weight | 1150KG | 1350KG | 2200KG | 1550KG |

| Model | YG-5-14S | YG-5-16S |

| Single wire(mm) | Round steel 5-14mm Deformed steel bar 5-12mm | Round steel 5-18mm Deformed steel bar 5-16mm |

| Double wire(mm) | Round steel 5-10mm Deformed steel bar5-10mm | Round steel 5-14mm Deformed steel bar 5-12mm |

| Max bending angle | ±180° | ±180° |

| Maximum towing speed | 110m/min | 110m/min |

| Maximum bending speed | 1000°/sec | 1000°/sec |

| Machine size | 3850*1200*2200mm | 4400*1500*2100mm |

| Device color | Yellow(customized) | Yellow(customized) |

| Pieces Processed | ≤2 | ≤2 |

| Air circuit system pressure | ≥0.8mpa | ≥0.8mpa |

| Total Power | 32kw | 52.5kw |

| Working temperature | -5°C~40° | -5°C~40° |

| Length accuracy | ±1mm | ±1mm |

| Angle accuracy | ±1° | ±1° |

| Average power | 5KW/h | 12KW/h |

| Total weight | 2200KG | 3000KG |

CNC Stirrup Bending Machine Application

The cnc stirrup bending machine is active in all kinds of construction projects.

- The construction of urban landmarks which needs it to creation of accurate and complex steel reinforcement bands.

- The rural infrastructure field, which also needs it to create accurate and complex steel reinforcement bands;

- The construction of rural infrastructure can also efficiently complete the task of basic rebar processing.

- In railroad, airport, and other large-scale transportation projects, it can fully meet the requirements of high strength and high precision of steel reinforcement bars. From civil construction to major infrastructure projects, it has its busy schedule.

3 Advantages of Steel Hoop Bending Machine

Compared with an ordinary steel hoop bending machine, cnc stirrup bending machine has unique advantages.

- It adopts advanced numerical control technology, the operation interface is simple and easy to understand, and workers can start without complex training.

- Automatic feeding, accurate bending in one go, compared with manual operation of the automatic stirrup bending machine, the efficiency is increased several times.

- Moreover, the machine can store multiple processing programs and switch between different bar shapes with one click, which greatly improves the production flexibility.

Automatic Stirrup Bending Machine Benefits for You

The introduction of the CNC stirrup bending machine has brought about significant changes to the construction industry. The problem of dimensional deviation, which used to occur easily in manual processing, has been solved, and the qualification rate of products has been greatly improved. Automated processing reduces material waste and production costs. Rapid production rhythm, so that enterprises can undertake more projects to enhance market competitiveness. At the same time, the equipment runs with low noise and perfect safety protection, creating a good working environment for workers.

Stirrup Bending Machine for Sale- YG Machinery

To get a good-quality CNC stirrup bending machine, it is crucial to choose the right manufacturer. YG specializes in the research and development of equipment, products with high cost performance, favored by small and medium-sized construction enterprises. We also focus on user needs, which can be customized according to the actual production of equipment, and provide attentive service. These excellent manufacturers contribute to the popularization of the stirrup bending machine and the development of the industry.