A water sand blasting machine is a device that uses a mixture of water and abrasive to spray at high pressure. When working, water acts as a “lubricant” to make the abrasive spray softer and avoid surface damage. For example, when removing the oxide layer of aluminum alloy parts, dry sandblasting may cause the surface to be rough. After the Wet Sand Blasting Machine is processed, the surface is smooth and bright, and no dust is generated, making the workshop air fresh and workers more comfortable to work. YG provides high-quality wet sandblasting machines. Click to get the machine price!

Water Sand Blasting Machine Parameter

| Machine models | YG400 | YG500 | YG600 | YG700 | YG800 | YG900 | YG1000 |

| Diameters(mm) | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Height(mm) | 1150 | 1150 | 1150 | 1250 | 1700 | 2000 | 2000 |

| Volume(cubic meter) | 0.26 | 0.26 | 0.26 | 0.3 | 0.6 | 0.8 | 1 |

| Pressure(Mpa) | 0.4-8 | ||||||

| Air consumption(cubic meter per minute) | 3 | ||||||

What Abrasives Should Be Used for Small Sand Blasting Machine?

Abrasives can be corundum, quartz sand, copper ore sand, brown corundum, dust-free sand, etc. The maximum particle diameter should not exceed 1.2mm, which is about the size of a millet grain.

Points to note when using abrasives:

- Particle size matching: A diameter exceeding 1.2mm may cause nozzle clogging. It is recommended to adjust according to equipment parameters (e.g., 1mm particle size is suitable for most industrial models).

- Mixing ratio: When mixing water and sand, the proportion of abrasive is usually 10%-30%. Too high a concentration will affect the injection pressure.

By reasonably selecting abrasive type and particle size, the cleaning efficiency and workpiece protection effect of the water sand blasting machine can be optimized, while taking into account cost and environmental protection needs.

Where Can a Wet Sandblasting Machine Be Used?

- The application scenarios are super wide! In the automotive industry, engine block deburring and wheel hub refurbishment can be easily done with it.

- In mold factories, it can accurately clean the surface residue of injection molds and extend the life of molds.

- For small processing plants, the small sand blasting machine model occupies a small area and is easy to operate.

- Metal base treatment before jewelry inlay and surface beautification of small hardware can be solved with one machine.

- Even for the anti-corrosion pretreatment of ship decks, the Water Sand Blasting Machine can quickly remove old coatings and rust, doubling the efficiency.

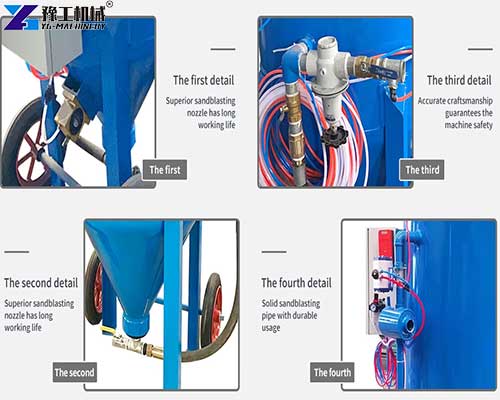

What Are the Components of a Sand Blasting Machine?

- The sandblasting tank is a “big granary” that can store a large amount of abrasive and water at a time to meet long-term operations.

- The spray gun is like a “brush” that can adjust the spray angle and strength to handle workpieces with complex shapes.

- The abrasive delivery system is stable and intelligent, and automatically replenishes abrasives according to spraying needs.

- The water circulation system is a “money-saving expert”. The recycled water can be reused after sedimentation and filtration, which can save a lot of water and abrasive costs every year.

Why Use a Sandblasting Machine?

Traditional manual grinding is inefficient and tiring; dry sandblasting is highly polluting and has high subsequent cleaning costs. Sand Blasting Machine can handle a large area and high speed with one device. Moreover, it can accurately control the injection pressure, and thin steel plates are not afraid of deformation. Most importantly, it has zero dust emissions and meets the strict environmental inspection requirements, so you don’t have to worry about being complained about and fined!

What Are the Advantages of Wet Sandblasting Machine?

- High efficiency: The processing area per hour is 3 times larger than the traditional method, and urgent orders can be delivered quickly.

- Environmental protection: There is almost no dust during operation, and it is easy to pass the environmental impact assessment.

- Material saving: The water circulation system and precise injection design reduce abrasive loss by 40%.

- The equipment is of reliable quality, and the key components are made of wear-resistant materials. Simple daily maintenance can ensure stable operation for many years.

Want to know the Wet Sandblasting Price? YG factory direct supply, 20% – 30% lower than the market price, full cost performance!

Wet Sandblasting Price from Yg Machinery

All Water Sand Blasting Machines of YG are sold directly at factory prices, without middlemen adding layers of price increases. Cooperating customers are spread across more than 20 countries, including the United States, Germany, and Southeast Asia, and the goods must be shipped within 3 days of receipt. The after-sales team is online 24 hours a day, 7×24 hours, and provides full guidance on equipment commissioning and fault repair. Choosing YG’s Wet Sandblasting Machine means choosing peace of mind and peace of mind!

Don’t miss this cost-effective equipment! The advantages of the wet sandblasting machine are visible, and YG manufacturers are strong enough to escort. In addition to this, we manufacture dry ice cleaners, sand blasting rooms, road blasting machines, and other related equipment! Click to consult now to get exclusive quotes and customized solutions, and open a new chapter of efficient production!