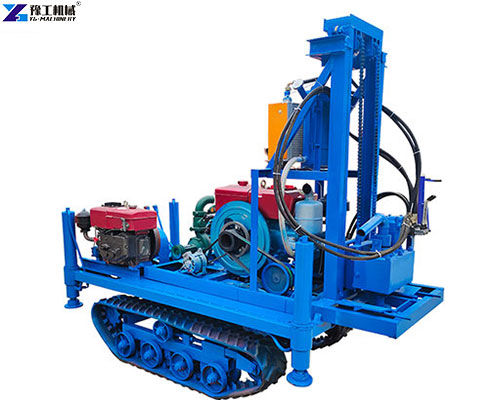

The anchor drilling rig from YG Machinery was successfully exported to Mexico for infrastructure and mining development projects. The client chose this equipment not only for its excellent drilling performance and flexible construction capabilities but also for its efficiency and stability in complex geological conditions. In addition, YG also offers down-the-hole drilling rigs, full hydraulic core drilling rigs, and rotary drilling rigs. Welcome to contact us anytime!

Anchor Drilling Rig Parameters

| Model | 6M | 15M | 30M |

| Track(mm) | 2300*3500 | 2300*4000 | 5000*3000mm |

| Width of crawler(mm) | 400 | 400 | 600 |

| Main arm | Double boom two sections | Double boom two sections | Double boom four sections |

| Drilling angle | Drillable flat hole/drillable inclined hole/drillable vertical hole | ||

| Drilling diameter | 5-300mm | 5-300mm | 5-300mm |

| Depth | 0-70m | 0-70m | 0-70m |

High-Efficiency Drilling Technology of Anchor Drilling Rig

- Fast hole formation capability: This equipment is equipped with a special casing-following drilling tool that enables stable hole opening through casing protection in unstable formations. It uses a conventional ball-tooth bit for final drilling, significantly improving drilling efficiency and ensuring high and consistent hole quality. This design is especially suitable for Mexico’s variable mining terrain, helping clients shorten project cycles.

- Adaptation to complex rock layers: As a professional rock anchor drilling machine, it easily handles hard rock formations, reducing bit wear and downtime. Client feedback from Mexican mines shows that its average drilling speed is 30% faster than traditional machines, greatly reducing labor costs.

- Intelligent operation: The equipment integrates an automatic control system, allowing operators to optimize the drilling process with simple parameter adjustments. This further enhances the potential of the anchor drilling rig, ensuring stable performance even in harsh environments.

Versatile Upgraded Crawler System

- Enhanced mobility: The upgraded crawler chassis improves equipment stability and allows optional jet grouting modules, making this ground anchor drilling rig adaptable to various engineering applications such as slope stabilization and foundation treatment. In Mexico’s urban construction projects, this flexibility helps clients switch between tasks quickly.

- Reduced ground requirements: With optimized crawler width and structure, the equipment can safely operate on soft or uneven terrain, reducing site preparation work. Clients reported that this anchor drilling rig performed exceptionally well in coastal soft-soil projects in Mexico, avoiding common ground settlement issues.

- Modular expansion: By integrating jet grouting functions, this ground anchor drilling rig can be seamlessly incorporated into complex projects, offering multi-purpose solutions that improve overall efficiency and reduce additional equipment investment.

Adaptability of the New Angle Adjustment Structure

- Flexible angle adjustment: The new angle adjustment mechanism allows the equipment to easily change drilling directions, covering a wide adjustment range from horizontal to inclined and vertical holes, greatly reducing site surface requirements. In Mexico’s mountainous tunnel projects, this anchor drilling machine helped clients overcome the limitations of narrow spaces.

- Improved operational convenience: The variable-angle design simplifies the alignment process, enabling multi-angle drilling without frequently relocating the equipment, thus reducing setup time. According to feedback, this anchor drilling machine played a crucial role in emergency repair projects, improving overall response efficiency.

- Compatibility with multiple applications: The structure is compatible with various drilling tools, making it suitable not only for anchor installation but also for other geological engineering purposes, extending the equipment’s lifespan and return on investment.

Practical Applications of Anchor Drilling Machine

- Mine reinforcement projects: In a large copper mine in Mexico, clients used our rock anchor drilling machine for rock layer anchoring, completing a one-month drilling plan in just two weeks. The equipment’s efficiency and reliability earned high praise from on-site engineers and led to additional orders.

- Urban infrastructure: In a metro extension project in Mexico City, the anchor drilling rig was responsible for foundation anchoring. Its stable performance ensured on-time delivery, and the client especially appreciated its wall protection capability in unstable formations, avoiding common safety issues.

- Customer feedback integration: Field surveys revealed that users highly valued the durability of the rock anchor drilling machine, setting a new benchmark for local engineering projects and attracting more business partnerships.

Sales and Service Support

- Localized training: We provide on-site training for our Mexican clients to ensure they fully utilize all the features of the ground anchor drilling rig. For example, during the first delivery, our experts provided maintenance guidance to reduce failure rates and extend service life.

- Customized solutions: Considering Mexico’s unique geological conditions, we offer tailored configuration suggestions to help clients optimize equipment performance. For instance, we recommend suitable anchor drilling machine models to maximize investment returns and ensure long-term cooperation.

YG Machinery will continue improving product performance and service quality to provide high-quality anchor drilling machine solutions for more global projects. Moreover, YG also offers reverse circulation drilling rigs, water well drilling rigs, and vertical shaft core drilling rigs. Feel free to contact us anytime for more product information!【WhatsApp/WeChat/Phone/Skype】+86 13837122632